Redefine what's possible: reduce rework and ensure quality.

Up to 70% less rework with monitoring & analytics software

Use AI-supported error detection in production to identify errors at an early stage, reduce costs and maximize OEE.

Intelligent quality assurance for stable, error-free production

With MHP's software products, developed in collaboration with leading automotive manufacturers such as Volkswagen and Porsche, you can automate your processes, minimize costs and effectively use real-time data to detect and correct errors at an early stage.

Our AI-supported software has been specially developed and optimized for the manufacturing industry to achieve maximum OEE (Overall Equipment Effectiveness) and ensure process stability. In many manufacturing companies, quality assurance is still carried out manually.

Manual processes are not only time-consuming, but also costly and error-prone. Without automated and data-based monitoring, sources of error remain undetected for too long and have a negative impact on process stability and customer satisfaction.

Success you can measure: innovative products for your production

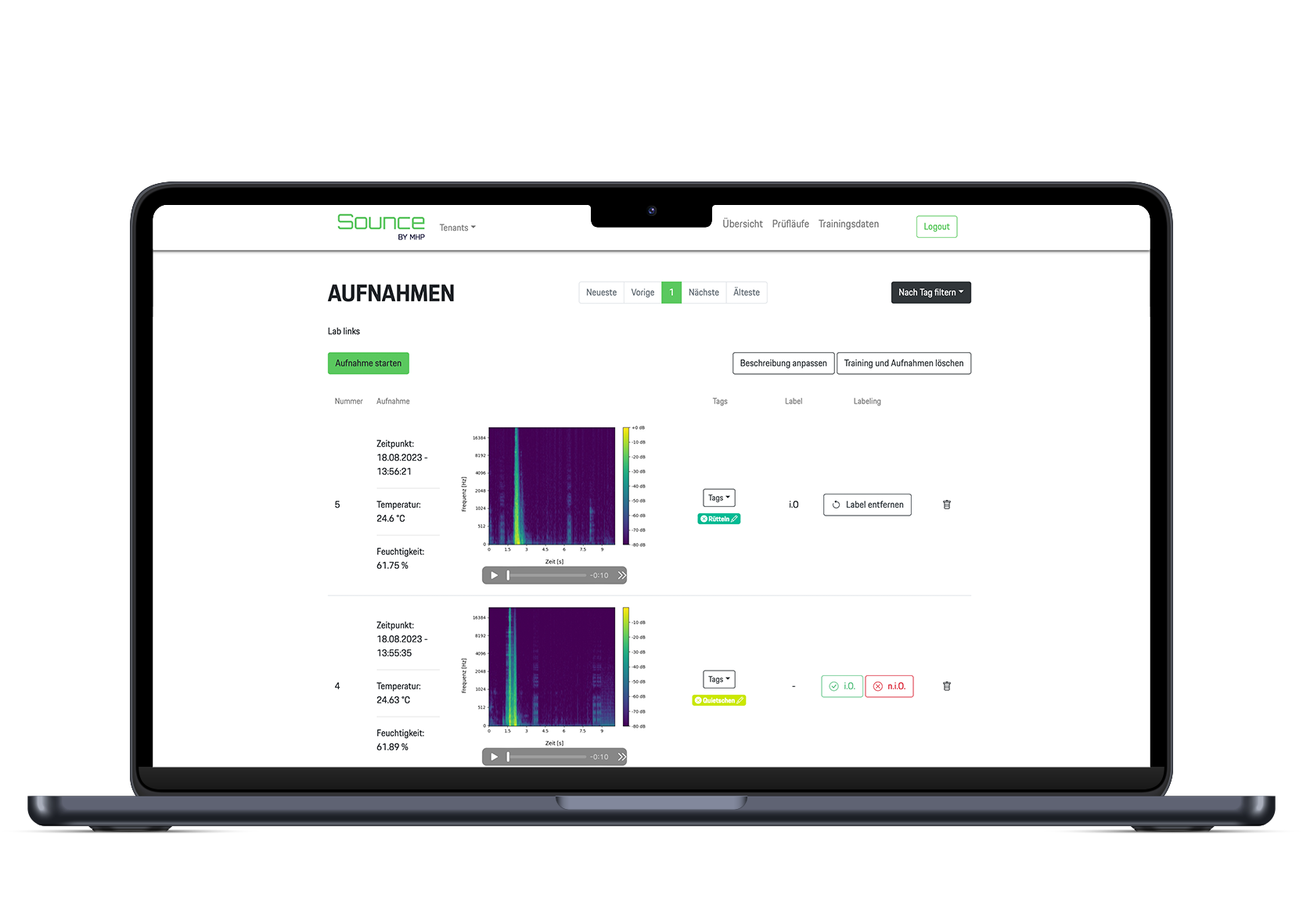

99 % accuracy in noise detection

Sounce offers companies precise noise detection with over 99% accuracy, which can reduce scrap costs by up to 20%.

Saving 5,000 hours of rework

paint_it paint_it detects quality anomalies in the paint at an early stage, enabling companies to avoid up to 5,000 hours of rework in the paint shop.

70 % less rework during screwing processes

With bolt_it, companies can significantly minimize rework and improve the quality of production processes by detecting anomalies in bolting processes at an early stage.

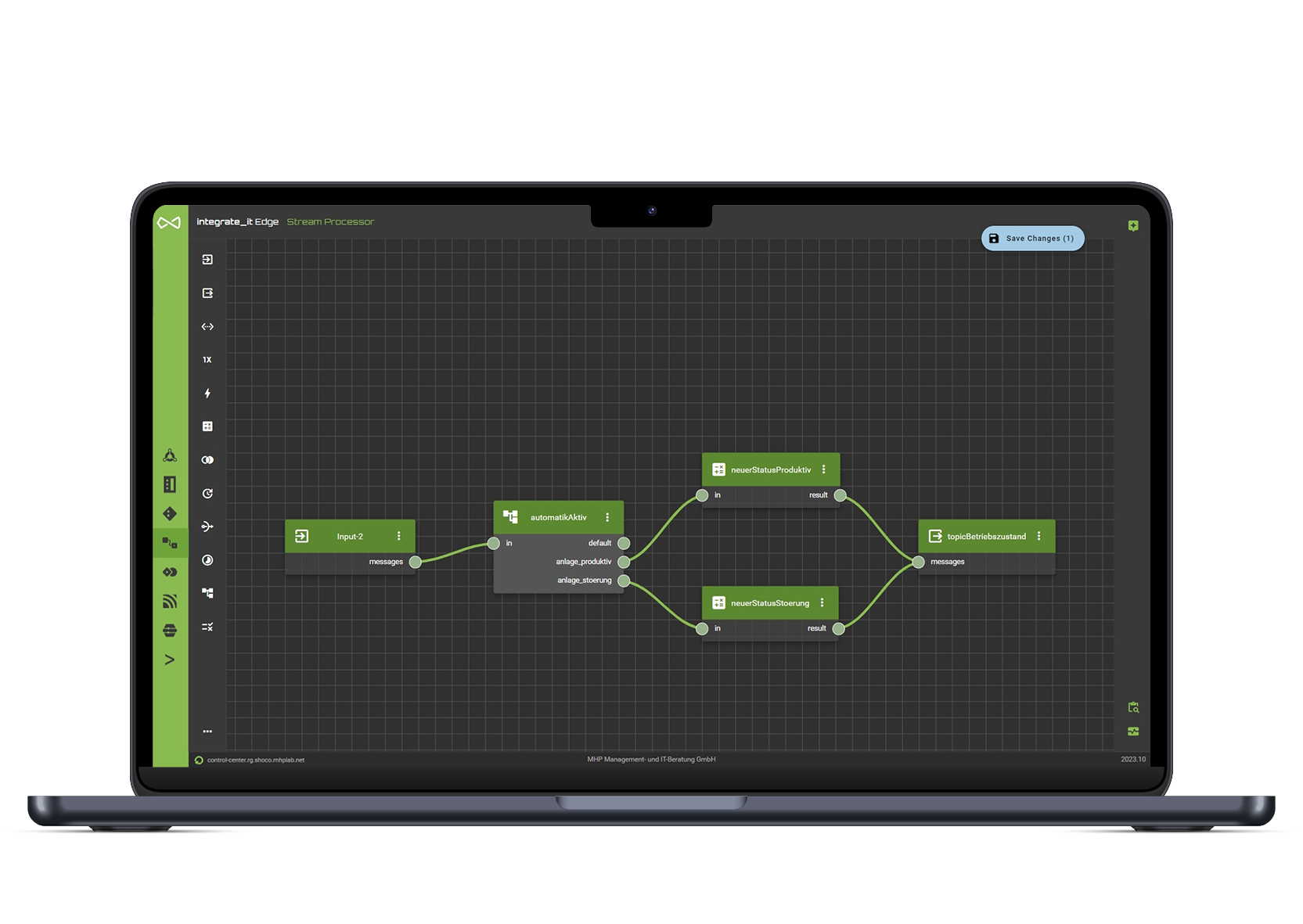

Increase efficiency by up to 8%

integrate_it standardizes and transforms machine data, helping companies to leverage the full potential of their production facilities.

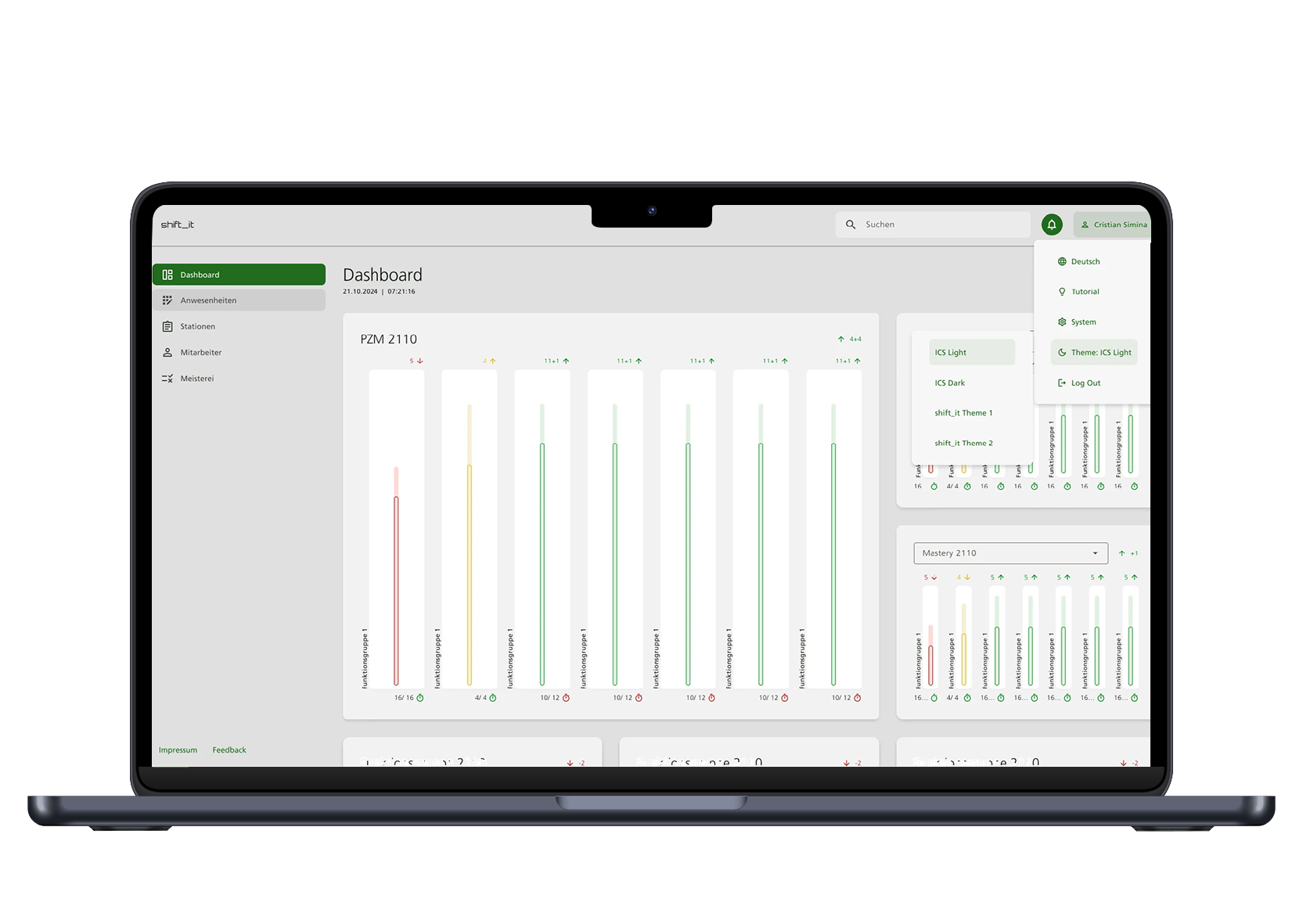

20 minutes time saving per work planning

The use of shift_it reduces the manual effort involved in staff scheduling, enabling companies to save valuable time and react quickly to short-term bottlenecks.

Are you ready to optimize your production processes and ensure the highest quality standards?

Find out how our Industrial Cloud Solutions can improve your production quality and reduce rework.

The benefits of our products at a glance

The Industrial Cloud Solutions from MHP offer you tailor-made software products that are specifically designed to optimize production processes and ensure high quality standards. Together with the Volkswagen Group and its brands Porsche and Audi, our products bring more scalability and security to your production.

With MHP's TISAX®-certified cloud products, you can improve production quality, minimize rework and at the same time ensure the highest data security and data protection standards.

Partnerships for future-proof production

MHP works closely with the leading cloud providers AWS and Microsoft.

These partnerships enable us to offer customized cloud services that are specifically tailored to the needs of the manufacturing industry. Thanks to state-of-the-art technologies, our solutions create the basis for more efficient, reliable production that ensures the highest quality standards.

In addition, we are expanding our offering through strategic partnerships with leading companies and technology providers to give our customers access to the best solutions for their production requirements.

As an Advanced Partner of AWS, MHP offers in-depth expertise in the implementation of cloud strategies and the digitalization of production processes. With over 400 certified consultants and services such as machine learning and IoT, we develop solutions that are specifically tailored to the requirements of quality assurance in production.

As a Microsoft Solution Partner, MHP supports companies with Azure-based solutions to optimize their production processes. Our more than 200 certified experts offer extensive experience in architecture development and implementation to support companies in their cloud transformation and achieve the highest quality standards.

Our products

Maximum production quality and efficiency at a glance.

paint_it

Optimized painting processes with intelligent quality control

Detect defects in paint thickness, color and texture in the shortest possible time thanks to intelligent data evaluation. The all-in-one solution for a flawless paint shop.

integrate_it

End-to-end digitalization on the store floor

Utilize the full potential of your machine data and achieve seamless integration and automation of your production processes.

bolt_it

Intelligent use of screwdriving process data

Improve your product quality and efficiency by intelligently evaluating and using screwdriving process data.

shift_it

Transparent and more efficient employee scheduling

Simplify your work scheduling with real-time display of attendances and absences as well as automated hiring processes before the start of a shift.

Sounce

AI-based noise anomaly detection in real time

Sounce enables reliable anomaly detection in production and development - for error-free processes.

TISAX® is a registered trademark of the ENX Association. MHP Management- und IT-Beratung GmbH has no business relationship with the ENX Association. The naming of the TISAX® trademark does not imply any statement by the trademark owner regarding the suitability of the services advertised here.