Your smart co-pilot for developing optimal material provision

Take your digital material flow planning in intralogistics to the next level and combine planning, analysis and optimization of your processes in one tool.

Our Customers

Easy to use, great value: Optimize your material flow with supply_it

supply_it makes planning and implementing even the most demanding logistics processes a piece of cake.

Our software solution covers the entire chain from incoming goods to production line.

Cost reduction of 10%

supply_it calculates the intralogistics costs for every component, process and product. This tool not only takes into account the countless possible combinations, but also determines the most cost-effective option.

Optimizations in under 5 minutes

Make changes to your intralogistics planning in seconds and get results with just a couple of mouse clicks. You can do optimization runs in only a few minutes.

ROI within 12 months.

Accelerate data-driven decisions with automated intralogistics processes. supply_it helps you to focus and improve your planning quality.

What our customers say:

“The joint initiative between MHP and Porsche Consulting represents a paradigm shift in logistics planning. Based on advanced technologies such as digital twins, it enables logistics processes to be designed more accurately and cost-efficiently.”

A unified source of information using a digital twin

supply_it creates a digital twin of your intralogistics that adapts the real environment of your company.

The implementation of these standards significantly increases efficiency.

Seamless Integration with ipolog for Enhanced Planning Simulations

Leverage supply_it to seamlessly transfer your planning data directly into ipolog. Visualize, simulate, and optimize your processes in real time. Identify bottlenecks early and make data-driven decisions for more efficient intralogistics!

supply_it explained

Benefits

The co-pilot makes work easier

Benefit from the intelligent and intuitive features of our powerful tool: Our smart co-pilot calculates the possible starting and process options for each component, taking into account costs and restrictions. It can also be seamlessly integrated into your existing tool ecosystem.

Increased planning speed

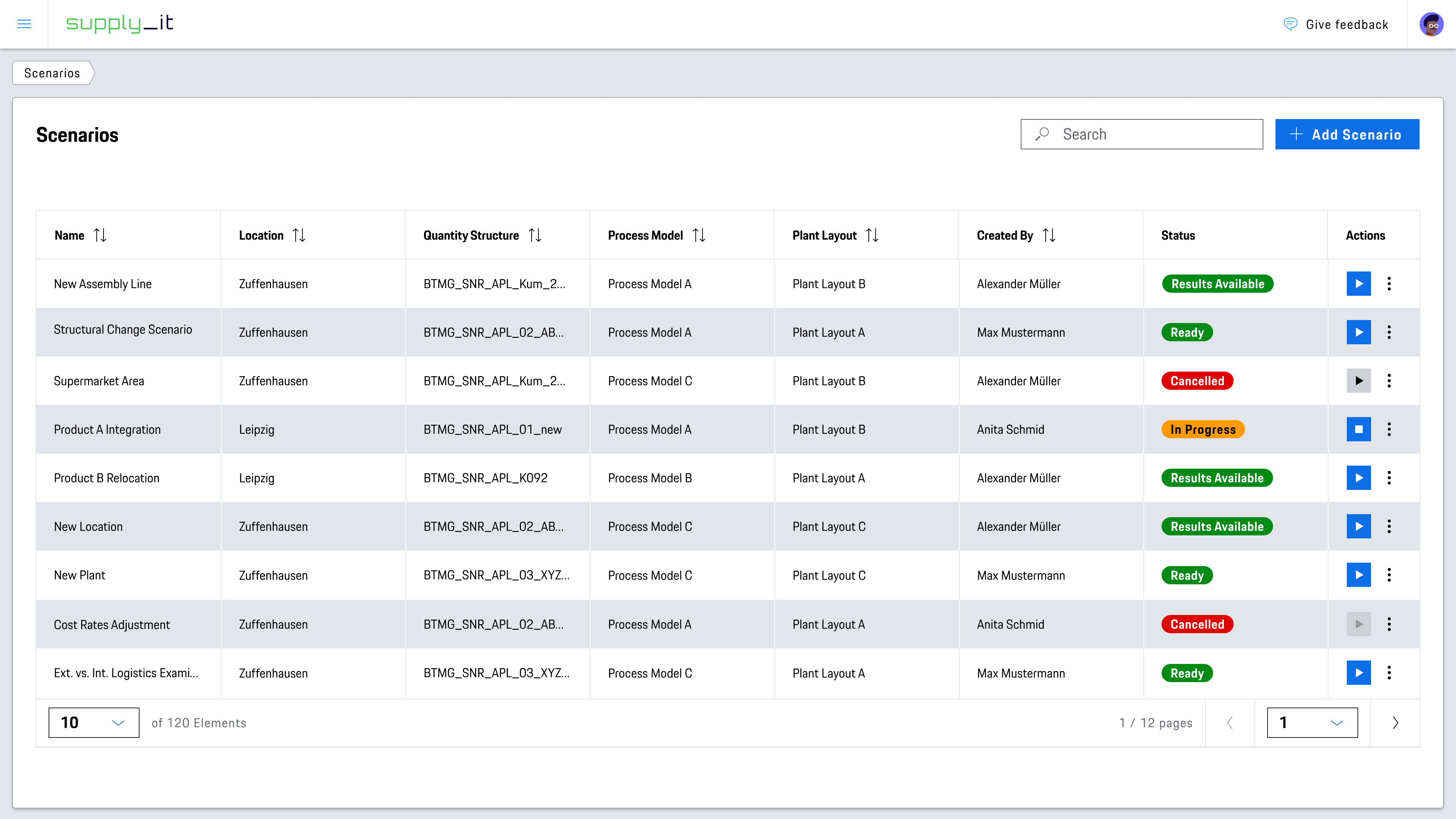

supply_it allows you to respond to change more quickly and efficiently, and adapt your processes faster. Optimizations that used to take weeks can be done in less than five minutes using this software.

Better planning quality

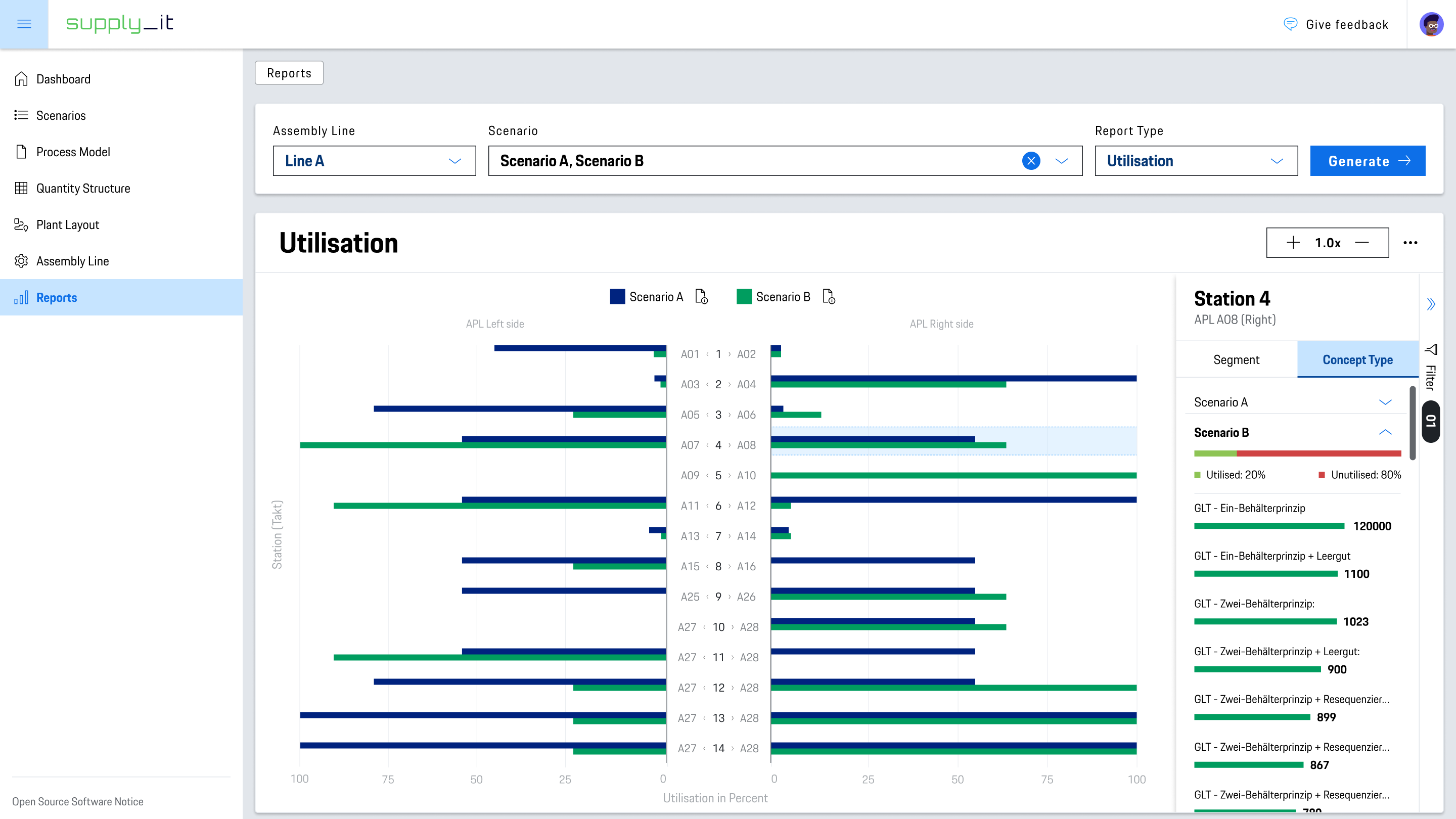

With advanced mathematical algorithms and an easy-to-use interface, supply_it lets you create more accurate and realistic logistics process models. This helps you optimize your resource utilization and reduce the risk of misplanning.

Reduced logistics costs

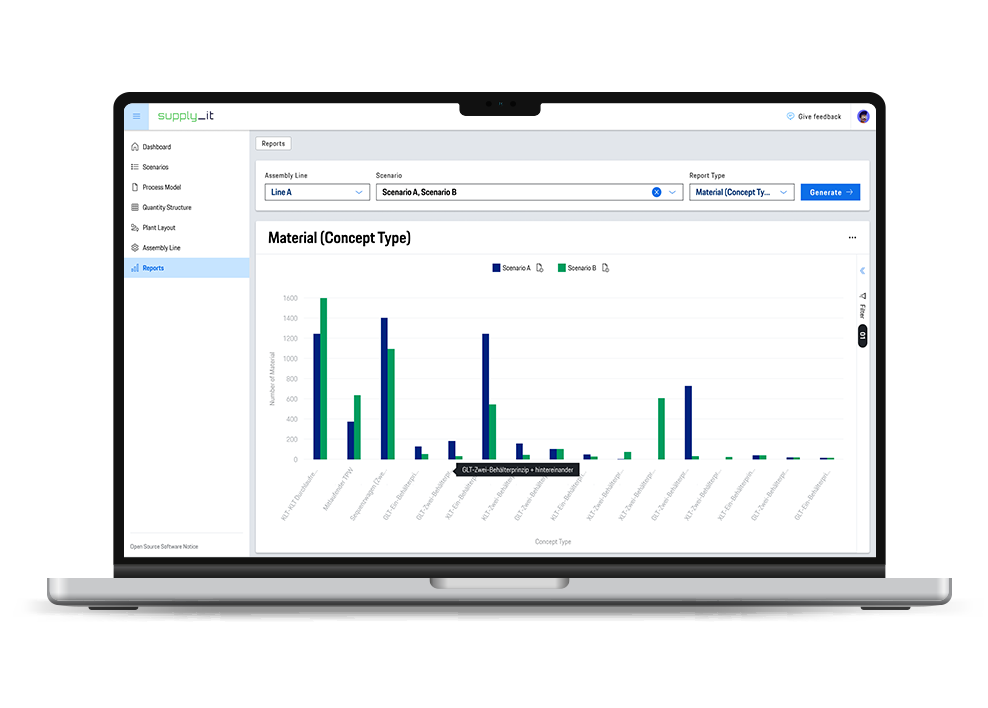

With supply_it you have a detailed insight into the various cost factors of your intralogistics. This allows you to identify areas where you can save costs, which will help you reduce your inventory costs and optimize your transport routes, resources and staffing levels.

Optimal use of existing storage areas

By analyzing and simulating different layouts and configurations, you can make your storage and production space more efficient. This not only improves space utilization, but also increases productivity.

FAQs

supply_it is a software solution for digital material flow planning in in-house or intralogistics. It optimizes internal material and product flows by calculating possible set-up and process variants and determining the configuration with the lowest total costs.

supply_it is particularly suitable for manufacturing companies with complex production and logistics processes, especially in industries such as automotive, aviation, agricultural machinery production and manufacturing.

supply_it is a digital twin of logistics processes. Digital mapping significantly increases the transparency of logistics costs and the speed with which logistics processes can be planned and optimized.

Yes, supply_it can be seamlessly integrated into existing tool ecosystems. It acts as the brain of digital logistics planning, combining and analyzing data from various sources. The results can then be transferred to existing systems, e.g. for visualization.

Changes in intralogistics planning can be made in just a few clicks. Compared to manual planning, which often takes days, supply_it enables optimization runs in just a few minutes.

Mathematical optimization can lead to considerable savings in in-house logistics costs of 5 to 20 percent. The specific amount of savings depends on the respective planning case (greenfield vs. brownfield, planning in the development phase vs. series optimization).

No, supply_it is adapted once to the specific framework conditions in the company. We recommend taking into account any foreseeable changes or innovations in the process model. By closely involving your employees, we ensure that most changes can be implemented independently. We are available at any time for major changes.

The level of optimization or digitalization does not play a role for the tool. However, it is helpful for implementation if standardized logistics processes are used. Otherwise, these must be developed as part of the implementation project.

The processes from goods receipt to final assembly are mapped. Goods receipt can take place inside or outside the plant at an external service provider. In addition, the main storage, picking and transportation processes are described based on their different characteristics. For example, a distinction is made between different storage systems in the storage processes.

By mapping automated processes as part of the implementation project, supply_it can identify the components that should ideally run through the automated process. In addition, the cost savings compared to the manual process can be determined. This supports the determination of the data for the specific business case for automation.

Explore more:

Efficient Material Planning Process Flow

MHP launches smart co-pilot for logistics planners