- Engineering & Production

- Published on: 13.02.2025

- 8:35 mins

More Efficiency, Lower Costs: How to Optimize Your Material Planning Process Flow

How can companies efficiently manage the increasingly complex material flow in today’s dynamic industry while simultaneously addressing challenges such as labor shortages and cost pressures? Many businesses still rely on traditional methods, which are often slow and error-prone. Manual adjustments to new variables carry the risk of overlooking critical factors or selecting incorrect values.

As skilled workers are in short supply and budgets shrink, internal logistics departments face mounting pressure to streamline processes and reduce costs. Digital products offer a solution: they ensure accurate calculations, save time, and enable more efficient operations in the long run. This not only dramatically reduces planning time, but also saves resources and money every day.

When Traditional Methods Fail: The Biggest Pitfalls in Material Planning Process Flow

Material flow planning is one of the central challenges for companies aiming to optimize their internal logistics processes. But why do traditional approaches repeatedly hit their limits?

Lack of cost transparency: Without comprehensive material flow analysis, companies often lack the necessary insights to assess the cost-efficiency of their processes.

Slow responsiveness: Changes in supply chains or production processes require quick adjustments – a challenge manual methods can't handle effectively.

Prone to errors: Small mistakes can have significant consequences for the entire logistics chain, especially when dealing with limited space capacity or complex processes.

New dimensions of complexity: With shrinking budgets and a shortage of skilled workers, the demands on material flow planning are becoming increasingly complex.

The growing complexity

Customers increasingly expect customized products, and the variety of required components is rising. Companies face the challenge of meeting these growing demands with existing warehouse and production space while maximizing cost efficiency. Often, the only option left is an expensive expansion of warehouse space.

But it’s not just space shortages that pressure logistics: complex structures require rapid, precise adjustments – a task that even experienced professionals can struggle to handle alone. Manual planning quickly reaches its limits here, as every change triggers additional chain reactions in the material flow process.

Why traditional methods often fail

Many companies still rely on manual planning approaches – a time-consuming and often inflexible process. Without digital support, professionals must decide in advance which method is likely to yield the best results. The problem: there’s no option to simulate and compare different scenarios.

Trusting in tried-and-true methods carries risks. People tend to rely on familiar patterns, even when they are not optimal. Innovations that younger professionals could bring are often met with skepticism. As a result, companies often fall short in their planning compared to the possibilities they could achieve with modern software solutions, such as more efficient material planning process flows.

Instinct-based decisions: when data is lacking

One of the biggest challenges in material flow planning is the lack of a solid data foundation. Without sufficient transparency over costs and processes, professionals often make decisions based on experience or gut feeling – a familiar approach, but rarely the most optimal.

The problem is particularly evident in companies with established workflows: old methods are rarely questioned, and inefficient processes go unnoticed. “We’ve always done it this way” becomes the biggest obstacle to innovation and savings. Additionally, personal preferences or biases toward certain suppliers can further drive up costs.

In contrast, data-driven decision-making offers tremendous savings potential. Companies that effectively utilize their data can objectively assess processes, derive improvements, and remain competitive in the long term, optimizing their material flow processes.

Digital Over Traditional: How to Put Your Intralogistics on the Path to Success

Digital products are fundamentally transforming intralogistics. With a digital twin, companies can virtually map all processes in their material flow planning and simulate countless scenarios – without the risk of disrupting ongoing operations.

A digital twin represents a virtual copy of all physical processes in your logistics chain. This enables precise simulation of workflows and early identification of potential bottlenecks. Automation complements this by efficiently and error-free handling repetitive tasks without human intervention. Together, digital twins and automation increase flexibility and provide maximum transparency across all logistics processes, enabling faster and more informed decisions.

Instead of waiting weeks for the results of manual calculations, digital tools deliver outcomes in just minutes. This allows professionals to respond flexibly and accurately to changes in the supply chain or customer demands.

Companies benefit from digital planning, particularly through three key advantages:

Faster scenario planning allows for timely comparison of different options and finding the optimal solution.

Real-time adjustments ensure that companies can flexibly respond to unforeseen changes, such as supply shortages or increased demand.

Proactive decision-making enables early identification and resolution of potential issues based on data-driven analysis – before they disrupt operations.

Thus, digital solutions not only increase efficiency but also enhance the resilience of logistics processes. Automation of optimizations reduces human errors and makes processes more efficient. Companies that embrace digital solutions gain not only speed and precision but also a clear competitive advantage in a dynamic market.

The Best Strategies for Efficient and Cost-Effective Material Flow Planning

Successful material flow planning requires a clear overview of material movement and storage, as well as the ability to optimally support production processes. Digital products offer significant advantages that traditional methods cannot match:

Automated scenario comparisons: Digital tools analyze and compare a wide range of options in a short amount of time to find the fastest and most cost-effective solution.

Layout planning with maximum efficiency: A clear overview highlights where costs occur, where savings are possible, and how cost efficiency can be sustainably improved – without manual assumptions or errors.

Process automation: Machines take over complex tasks that could be impacted by human fatigue, inattention, or illness.

Equally important is the choice of software that provides full cost transparency. Only through data-driven decisions can companies ensure that no inefficient processes are overlooked, and costs are effectively reduced.

supply_it: Your Digital Copilot for Intralogistics

MHP's intralogistics software, supply_it, takes your material flow planning to the next level. As a "digital copilot," it offers powerful features to precisely analyze and efficiently manage even the most complex logistics processes.

Core features of supply_it

Digital twin for maximum transparency: supply_it creates a digital representation of your intralogistics, allowing you to test various scenarios risk-free without disrupting ongoing operations.

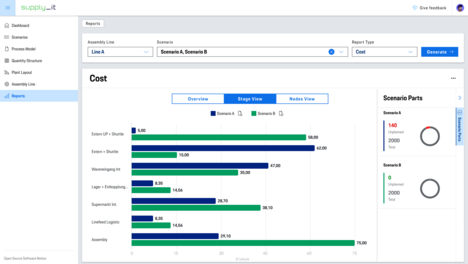

Lightning-fast scenario planning: Compared to manual methods, supply_it reduces planning time to just a few minutes, enabling you to explore more alternatives and find the optimal solution.

Real-time cost transparency: The software provides detailed visualizations of the entire cost structure of your intralogistics, revealing potential savings down to the smallest component.

Unique benefits

Easy data integration: supply_it seamlessly reads and processes data from SAP and other ERP systems. Organizations already using these platforms can leverage the software's benefits more rapidly.

User-friendliness: The intuitive platform allows your experts to make adjustments quickly and independently.

Scalability: Whether a medium-sized business or a global corporation, supply_it flexibly adapts to your requirements.

Proactive decision support: The data analysis provided by supply_it offers data-driven insights, enabling clear, fact-based decisions.

Success Story: Porsche

A prominent user of supply_it is Porsche. With the software, the company optimized over 3,000 components and reduced its intralogistics costs by an impressive 10%.

AWS and supply_it: The Perfect Foundation for Your Intralogistics

The powerful infrastructure of Amazon Web Services (AWS) forms the technological backbone of supply_it. With AWS as the cloud provider, the software ensures flexibility, security, and scalability. Companies can efficiently process large data volumes, perform rapid scenario calculations, and seamlessly integrate the software into existing systems.

Thanks to AWS's flexibility, supply_it dynamically adapts to the needs of various company sizes and industries. This robust foundation enables efficient operation even in a global environment with rapidly changing market conditions.

Discover the Potentials of supply_it

Would you like to learn more about the benefits of supply_it? Download our free whitepaper and gain detailed insights into optimizing your intralogistics.

Download the whitepaper now

Conclusion: Why Digitalization Secures the Future of Your Material Flow Planning

Digitalizing material flow planning offers companies immense advantages: saving time, reducing costs, and increasing the efficiency of internal logistics processes. With precise analysis and enhanced transparency, businesses can make informed decisions and adapt flexibly to changes.

supply_it by MHP is a powerful intralogistics software that stands out with innovative features like real-time cost transparency and rapid scenario planning. Companies like Porsche have already reaped the benefits, implementing significant optimizations.

In an increasingly dynamic and competitive market, digital solutions like supply_it will play a critical role in ensuring success. Those who invest in these technologies today will secure key advantages and stay one step ahead of the competition.

FAQ

When products are modified or entirely new ones are produced, planning in intralogistics becomes increasingly complex. Capacities must be redistributed without causing disruptions. While manual planning often takes several days or even weeks, supply_it can simulate these changes within minutes. This provides a critical advantage in fast-paced industries. This feature is also invaluable when you need to respond promptly to market changes. By leveraging digital solutions like supply_it, businesses can navigate these challenges efficiently and maintain their competitive edge.

When you can analyze the costs of every single component and process, it opens up opportunities for identifying potential savings. The tool supply_it provides a detailed cost breakdown through clear visualizations and a structured overview. Without this level of cost transparency, cost-saving efforts would rely heavily on assumptions rather than data-driven insights. By using supply_it, businesses can make informed decisions and unlock significant efficiency gains.

Companies with complex and multi-stage logistics processes are particularly well-suited to benefit from the supply_it tool. The intralogistics software maps all processes, from goods receipt to placement on the production line. It doesn’t matter whether the goods are received directly at the plant or through an external service provider – supply_it also accounts for transportation methods and processes. Additionally, the tool distinguishes between various storage systems, offering a comprehensive solution tailored to diverse logistical needs.

supply_it sets itself apart by enabling the creation of a digital twin of all your logistics processes. This allows you to conduct simulations and optimizations that would be impossible to execute during live operations. The tool significantly accelerates the planning and optimization of logistics processes while providing clear cost transparency. By combining speed, precision, and comprehensive visualization, supply_it surpasses the capabilities of conventional intralogistics planning tools.