- Blog , Cloud

- Published on: 06.04.2023

- 4:03 mins

Driving Safe and Efficiently

- Today’s vehicles are moving beyond being a simple means of transportation and are evolving into connected Internet of Things (IoT) devices.

- In this context, the digital twin concept can be utilized to address complex challenges related to mobility.

- MHP and AWS have collaborated to build a modular, scalable digital twin solution to address the challenges of electric vehicles, specifically EV battery performance.

The automotive industry is experiencing a fundamental transformation, moving beyond simple means of transportation and evolving into connected IoT devices that are changing the way we think about vehicle ownership and usage. This change in vision is driving the industry towards AI-accelerated digital twins to address challenges such as smart charging, battery health monitoring, predictive maintenance, fleet management, and circular economy.

A digital twin is a virtual representation of a physical system that is dynamically updated with data to mimic the structure, state, and behavior of the physical system. The breadth of digital twin use cases has led Amazon Web Services (AWS) to propose a 4-level index to help customers categorize their use cases and understand the services, technologies, data, and models needed to build and deploy their digital twin at scale.

MHP, an AWS Advanced Tier Services Partner with expertise in mobility and manufacturing, has collaborated with AWS to build and deploy a Level 4 digital twin for an electric vehicle as a means for monitoring and analyzing batteries of electric vehicles (EVs) by utilizing live data, fleet knowledge, and AI. The focus of this digital twin is to monitor and predict battery health and performance by learning driver behavior and battery characteristics from the fleet.

Solving the Electric Vehicle Battery Challenge

The electric vehicle battery challenge is central to battery producers, OEMs, and users. Each electric vehicle is exposed to different environmental conditions and usage patterns, resulting in unique batteries that require specific operational performance calculations. Monitoring and predicting battery characteristics such as the state of health (SoH) and state of charge (SoC) allows addressing topics such as range anxiety, predictive maintenance, residual value, and second life for EVs. However, today’s physics-based models developed for calculating such parameters in batteries have two main downsides: low accuracy and high computation costs.

The solution deployed by MHP and AWS uses a hybrid physics and data-driven approach, allowing organizations to create operational models that can run in near-real time and include the effects of real-world factors by leveraging the operational vehicle data. The solution needs to be scalable to a great number of vehicles and modular to ensure additional components can be added as the digital twin becomes more complex. Additionally, it needs to be able to provide a scalable mechanism to automatically recalibrate the models of individual EVs to ensure they continue to make accurate predictions.

Complex Architecture, Easy Solution

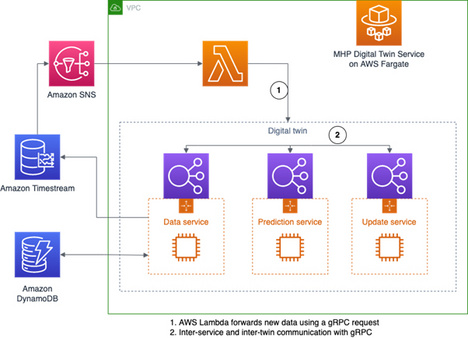

The architecture of the solution uses AWS IoT FleetWise to feed simulated vehicle data into an Amazon Timestream database. The data is consumed by the custom-built MHP digital twin service, which stores the prediction metadata in Amazon DynamoDB and the predictions results back into Amazon Timestream. Prediction results are fed into AWS IoT TwinMaker and are used in Amazon Managed Service for Grafana to allow a fleet operator to monitor the state of health and other vehicle-based information in an easy-to-use dashboard. This is shown in Figure 2.

The MHP digital twin service is key to the Level 4 digital twin solution and handles passing operational data to the digital twin model, running the model, calculating the model error, and recalibrating the digital twin model when needed. The service leverages model calibration techniques developed as part of the aws-do-pm open-source framework.

The MHP digital twin service has two key features to enable a modular digital twin that can grow as new components are added. First, the digital twin is divided into submodules, each of which are represented by their own digital twin. Second, each digital twin is divided into three modules (Figure 3) – a data service, update service, and prediction service – to enable a Level 4 living digital twin to use measurements to update the model in order to improve predictions as new data becomes available.

In summary, MHP and AWS have collaborated to build a modular, scalable digital twin solution to address the challenges of electric vehicles, specifically EV battery performance. This solution is a Level 4 living digital twin per the 4-level index proposed by AWS. The solution focuses on predicting the state of health of an EV battery based on driving patterns, using a driver digital twin and a battery digital twin.

AI Offers Limitless Possibilities

Digital twins have the potential to revolutionize the automotive industry, offering limitless possibilities for smart transportation. With AI-accelerated digital twins, the industry can address complex challenges related to mobility, such as smart charging, battery health monitoring, predictive maintenance, fleet management, and circular economy.

To learn more, please read MHP’s whitepaper, read our detailed APN blog post, and watch our webinar.