- Blog, Engineering & Production

- Published on: 30.09.2024

- 12:36 mins

Efficient and Organized: SAP Logistics Templates in the Manufacturing Industry

In the manufacturing industry, logistics and supply chain processes present significant challenges. Companies must not only manage complex operations but also respond adaptably to market demands. This is especially true in sectors like automotive, machinery, and pharmaceuticals, where the balance of delivery timelines, quality, and availability is essential. Inefficient processes can lead to high costs. Standardized, structured, and easily adaptable solutions like SAP logistics templates hold great potential: they represent standard processes while allowing for individual customizations, providing a clear overview without unnecessary complexity.

In addition to the challenges of initially implementing SAP logistics templates within corporate structures, the transition from SAP Warehouse Management (WM) to SAP Extended Warehouse Management (EWM) currently poses a challenge for companies already using SAP logistics templates. While this transition offers numerous benefits, it requires careful planning and adaptation of existing processes.

In this blog post, we will explore the advantages of logistics templates and how MHP can assist you with their introduction, implementation, or transition.

SAP Logistics Templates as a Solution for Logistics Process Challenges

To understand the benefits and implementation of SAP logistics templates, it's helpful to have some basic information about the modular structure of SAP S/4HANA:

Overview of the general functionality of SAP S/4HANA

SAP S/4HANA is the latest generation of the SAP ERP suite, providing your company with a central platform to integrate and optimize all business processes. With SAP HANA's in-memory technology, data is processed in real time, enabling faster decision-making and greater efficiency. S/4HANA allows you to seamlessly connect all core processes – from finance to sales to logistics. This significantly simplifies complex business operations, particularly in the manufacturing industry, where large volumes of data must be processed quickly to avoid costly production downtime.

A key advantage of S/4HANA is its modularity. You can tailor the platform to your specific needs by integrating industry-specific modules such as SAP EWM for logistics or SAP PP (Production Planning) for manufacturing planning. This flexibility ensures that your company can leverage the benefits of modern technologies while still adhering to standardized processes.

Logistics templates in SAP – spotlight on SAP EWM

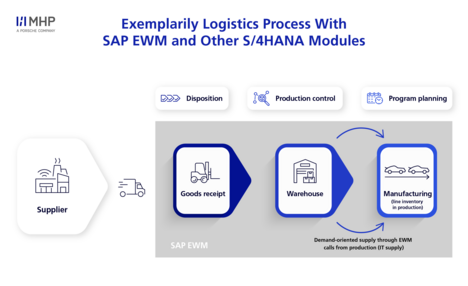

In the logistics area, SAP S/4HANA offers a variety of solutions supported by standardized templates. These templates make it easy to implement best practices quickly and efficiently, without the need to redesign processes from scratch. A key module that plays an essential role in logistics is SAP EWM. This module is specifically designed for managing and optimizing warehouse processes and provides a comprehensive solution for controlling the entire warehouse lifecycle.

SAP EWM enables the management of large warehouse complexes, optimization of goods movements, and integration of automated systems. With SAP EWM, companies can comprehensively map and control their warehouse processes from receiving to shipping. Additionally, real-time inventory monitoring enhances transparency and efficiency.

An example of using an SAP EWM template could look as follows:

- Goods Receipt: Upon the arrival of raw materials in the warehouse, the system records the goods and automatically assigns them to the correct storage location. This takes available storage capacities and the optimal storage strategy into account, minimizing travel distances and ensuring efficient warehouse utilization. Processes can be automated based on individual conditions.

- Storage and Production: The system tracks and calculates every demand in real time. When a product is needed from a specific area of the warehouse at the production line or another location, an optimized route is determined, and the movement is organized efficiently. Relevant consumption postings and production feedback are integrated seamlessly. Automated technologies, such as driverless transport systems or automated storage systems, can be directly integrated into EWM.

- Picking and Goods Issue: When a customer order is received, SAP EWM ensures that the required products are picked quickly and efficiently. Using templates for the picking process allows the workflow to be standardized and expedited. The seamless integration with transportation management ensures smooth shipping and generates all relevant information, such as packing lists and delivery notes.

The Advantages of SAP Logistics Templates are Numerous

The implementation of SAP logistics templates offers your company numerous benefits. Here are some of the key advantages in detail:

1. Standardization of cross-plant logistics processes

A key advantage of SAP logistics templates is the standardization of logistics processes across different plants. Uniform workflows reduce complexity in globally operating companies and minimize sources of error, as established guidelines are followed. This makes operations more efficient and eliminates the need for individual custom developments for each plant. Additionally, this standardization increases transparency and provides a better foundation for collaboration throughout the organization.

2. Accelerated implementation

SAP logistics templates enable faster implementation of processes, especially at new locations or during project rollouts. Since the templates are based on proven processes, you can leverage established workflows without having to develop new processes from scratch. This is particularly advantageous for companies expanding or opening new plants, as the templates can be quickly transferred and implemented without errors.

3. Cost reduction

Utilizing a single SAP logistics template for multiple locations or projects results in significant cost savings, as it eliminates the need for extensive customizations and developments for individual plants. This reduces both development efforts and resource consumption. Additionally, ongoing costs for site-specific optimizations are also eliminated, further lowering overall operational costs in the long run.

4. Improved user acceptance

Standardized processes significantly enhance user acceptance. Since workflows are uniformly designed across locations, training and onboarding phases are shortened. Additionally, employees only need to familiarize themselves with the individual process once, which reduces the learning curve and minimizes training effort. At new locations, employees encounter familiar processes, which boosts both productivity and user satisfaction.

5. Simplified system maintenance and support

The centralized management of SAP logistics templates simplifies system maintenance and support. Maintenance tasks, bug fixes, and new releases are handled centrally, reducing the effort required at each location and increasing system availability. Issues are resolved more quickly, improving the overall stability of the system.

6. Complete integration across the entire supply chain

A unified template facilitates the integration of logistics processes across the entire supply chain. Since all locations and departments utilize the same workflows, interoperability is simplified, supporting smoother collaboration and better coordination. Standardized processes reduce interface issues and enhance the overall performance of your company.

Time Is Running Out: Starting in 2027, SAP EWM Will Replace Its Predecessor, SAP WM

In the realm of SAP-supported logistics solutions, SAP Warehouse Management was long the standard solution for managing and controlling warehouse processes. However, with the transition to SAP S/4HANA, SAP Extended Warehouse Management will completely replace the existing SAP WM. Support for SAP WM will end in 2027, and companies are encouraged to transition their existing warehouse solutions to the new SAP EWM.

What is SAP EWM? What is SAP WM?

SAP Warehouse Management (WM) was the leading solution for warehouse management within the SAP ERP system for many years. It offers functionalities for managing storage locations, inventory, and goods movements within a warehouse. SAP WM is a proven solution widely used across various industries, particularly in manufacturing. It will continue to operate until 2027.

SAP Extended Warehouse Management (EWM) is the new, more powerful module developed as part of SAP S/4HANA. EWM provides a more comprehensive and flexible solution for complex warehouse processes. It enables the management of not only large warehouses but also automated storage and conveyor systems. Unlike WM, EWM offers deeper integration across the entire supply chain and supports advanced functions such as slotting, cross-docking, and detailed planning of warehouse resources.

SAP WM vs. SAP EWM:

Functionality: EWM offers a wider range of features than WM, particularly in managing large and complex warehouse processes.

Flexibility: While SAP WM is designed with a more rigid framework for processes, SAP EWM offers greater flexibility, allowing companies to tailor their warehouse processes in more detail and customize them to their needs.

Integration: SAP EWM is deeply integrated into the SAP S/4HANA environment, while SAP WM is still based on the older ERP platform and will no longer be supported in the new environment.

Deployment Options: SAP EWM can be implemented as a decentralized system with interface communication, as an embedded system within S/4HANA, or through cloud-based solutions. This flexibility is not available in SAP WM.

Challenges of the transition

The impending replacement of SAP WM by SAP EWM presents significant challenges for many companies. Particularly for businesses that have developed custom solutions and modifications in SAP WM over the years, the task of transitioning these to the new SAP EWM module can be daunting. This is not a straightforward process, as many of the processes implemented in WM cannot be directly transferred to EWM. Companies must review their existing workflows and adapt them to the expanded and sometimes differently structured functionalities of EWM.

Another challenge lies in the rollout strategies themselves. It is often unclear how to strategically approach the migration to SAP EWM. Different corporate structures and specific requirements necessitate tailored approaches for each case. Should the implementation be gradual or simultaneous for all locations? How can legacy systems be operated in parallel during the transition phase? How can a successful rollout be executed in various plants with differing physical and logical setups? These questions often lead to uncertainties that require a well-thought-out migration strategy.

How MHP Supports You in Transitioning to SAP EWM or Implementing SAP Logistics Templates

Transitioning to SAP EWM or implementing SAP logistics templates requires detailed planning and specialized expertise. As an experienced consulting firm, MHP supports your company in successfully navigating these complex transformation processes.

Example rollout strategy by MHP: step-by-step to success

MHP relies on well-thought-out and proven rollout strategies that enable companies to successfully implement SAP EWM or logistics templates in multiple phases. This process starts with the careful selection of a pilot site and spans several rollout phases, during which the template is continuously developed and adapted to the requirements of various locations. We approach the rollout in the following manner, for example:

- Site Selection: In the first step, the pilot site is determined. Typically, we choose the location that covers the maximum number of relevant logistics processes. This pilot site serves as the foundation for later scaling to other facilities and as a reference point for creating a flexible, adaptable template.

- Template Creation: At the pilot site, all logistics processes are analyzed and tailored to the requirements of SAP EWM. The resulting prototype covers the essential processes based on the site selection and is flexible enough to meet the needs of other locations.

- Rollout 1: After establishing the template at the pilot site, the first rollout follows. A fit-to-template analysis assesses how well the template aligns with the conditions of the next site. Based on this analysis, the template is adjusted as needed.

- Further Rollouts: The template is gradually expanded to additional sites and supplemented with additional processes. Possible differences in structure and infrastructure must be considered, and appropriate adjustments made accordingly.

Of course, the strategy implemented in your case will be tailored to the specific requirements of your company and may therefore differ from the strategy presented here.

Expertise in S/4HANA transformation processes

MHP has deep expertise and years of experience in transformation processes involving SAP S/4HANA. We support your company not only in technical implementation but also in strategic alignment, optimization of business processes, and ensuring a smooth transition. Through close collaboration with numerous companies, MHP understands the challenges in logistics-intensive industries and can provide tailored solutions that are both efficient and future-proof.

These MHP Logistics Tools Are Available Today

MHP's expertise in logistics is reflected not only in its consulting services for clients but also in products that are already available today. Two particularly relevant products from MHP are supply_it and the Fleet Executer:

supply_it: optimization of material flow planning in intralogistics

supply_it optimizes material flow planning in intralogistics by determining the best configuration before template implementation. It calculates the lowest total costs and simulates various scenarios to identify the most efficient logistics processes. As a planning basis, the tool ensures that warehouse processes are optimally prepared before implementation, minimizing errors and the need for later adjustments.

Fleet Executer: management and control of vehicle fleets with SAP EWM

The MHP Fleet Executer manages manufacturer-independent vehicle fleets with SAP EWM and enables real-time monitoring of transport vehicles. The tool optimizes the assignment of transport orders and route planning, taking into account individual lifts, gates, and other sensors, thereby reducing downtime and shortening transport routes. By integrating with SAP EWM, it automates material movements and enhances the efficiency of warehouse logistics.

Conclusion: Master the Challenges of Logistics Processes with MHP and SAP Logistics Templates

Implementing SAP logistics templates offers companies in the manufacturing industry an excellent opportunity to optimize their complex and costly logistics processes. Through standardized yet flexible templates, you can achieve efficiency gains, reduce errors, and lower costs. Particularly, the transition from SAP WM to SAP EWM starting in 2027 presents new challenges for companies, but these can be managed through a well-planned and phased approach. MHP provides comprehensive support for the transition, implementation, and customization of SAP EWM, as well as the implementation of SAP logistics templates to ensure that the solutions meet the specific needs of each company.

FAQ

The SAP logistics modules include, among others, SAP Extended Warehouse Management (EWM) for warehouse management, SAP Transportation Management (TM) for transportation planning and control, and SAP Material Management (MM) for procurement and inventory management. These modules cover key areas of logistics and are deeply integrated into SAP S/4HANA.

SAP in logistics includes a range of software solutions that help companies efficiently manage and optimize their logistics processes, such as warehouse management, transportation planning, and material flow. With modules like SAP EWM, SAP TM, and SAP MM, SAP enables integrated and transparent handling of the entire supply chain.

In the warehouse, the SAP Extended Warehouse Management (EWM) module is primarily used, offering comprehensive functions for warehouse management and optimization of goods flows. In smaller or less complex warehouses, SAP Warehouse Management (WM) may also be used, but it will be replaced by SAP EWM by 2027.