- MHP exhibiting at Motek 2024 in Stuttgart in Hall 3, Stand 3103

- Presentation of intelligent industrial cloud solutions (ICS)

- Trade fair highlights: bolt_it, Sounce, paint_it and integrate_it

- Practical demo: presentation with a combined system and a vehicle body replica

Ludwigsburg – The management and IT consultancy MHP will be represented at the 42nd Motek in Stuttgart from 8th to 11th October 2024. At the international trade fair for automation in production and assembly, MHP will present the industrial cloud solutions bolt_it, Sounce, paint_it and integrate_it. “The targeted use of SaaS solutions can help leverage considerable efficiencies, particularly in the area of quality assurance. We will be presenting solutions precisely for this purpose at Motek, using vehicle production by way of example,” says Michael Appel, Partner at MHP.

AI-based quality assurance and control

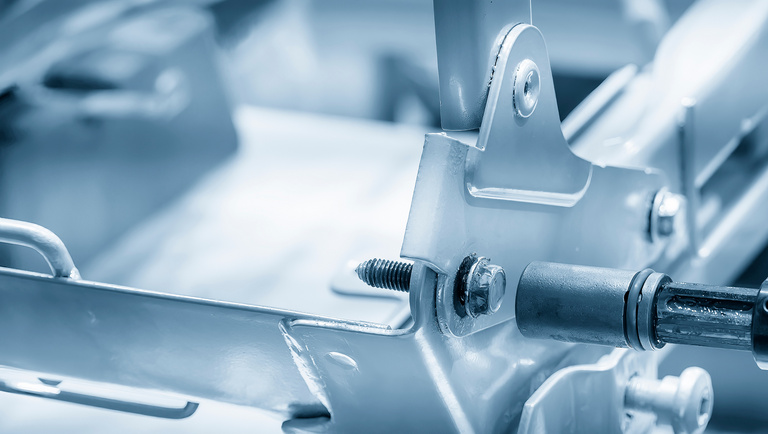

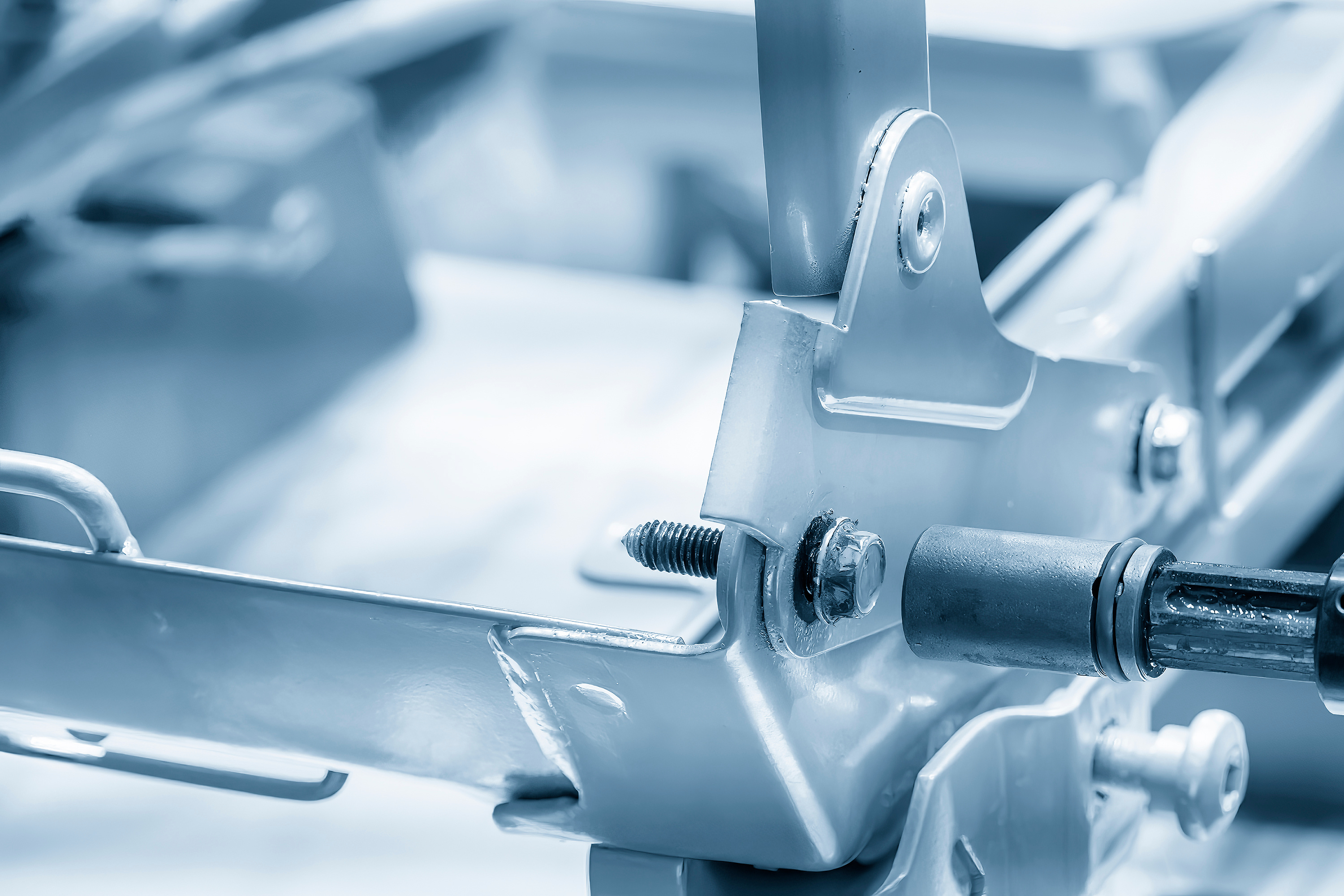

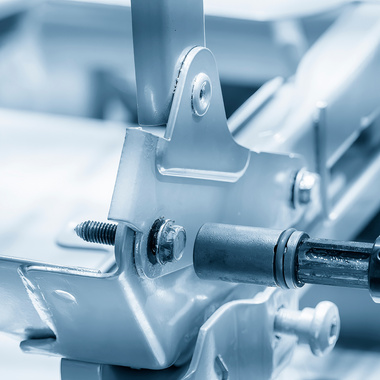

The presented ICS solutions focus on quality assurance and control: bolt_it facilitates faster decision-making through the intelligent use of bolting process data using AI. The manufacturer-independent solution provides a comprehensive overview of the bolting processes and helps improve product quality and production efficiency by unlocking the full process data potential.

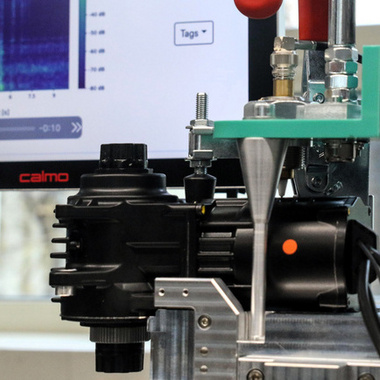

Cost effects and efficiency potentials can also be realized using Sounce: The AI-supported acoustics monitoring software detects sound anomalies in quality assurance or in the course of component qualification. It involves causing the units or components being tested to vibrate, creating a characteristic sound pattern. If this deviates from the reference pattern learned by the AI, the system detects this as an anomaly and issues an alert. Defects can thus be detected more quickly and reliably than with the commonly used spot checks on test rigs and in development. The process involves minimally invasive sensor equipment on the end-of-line test stand that generates raw data, enabling the AI to be trained. The required quality criteria can subsequently be determined. The resulting algorithm is uploaded to the cloud and made available there.Cost effects and efficiency potentials can also be realized using Sounce: The AI-supported acoustics monitoring software detects sound anomalies in quality assurance or in the course of component qualification. It involves causing the units or components being tested to vibrate, creating a characteristic sound pattern. If this deviates from the reference pattern learned by the AI, the system detects this as an anomaly and issues an alert. Defects can thus be detected more quickly and reliably than with the commonly used spot checks on test rigs and in development. The process involves minimally invasive sensor equipment on the end-of-line test stand that generates raw data, enabling the AI to be trained. The required quality criteria can subsequently be determined. The resulting algorithm is uploaded to the cloud and made available there.

A further digital quality assurance tool from the ICS portfolio is paint_it: This monitoring system enables digital quality monitoring for paint. Various characteristics are evaluated, including paint layer thickness, color hue and surface finish – in a cloud-based and hardware-independent process. The data collected via sensors is checked against the company-specific tolerances and references. Through the recognition of trends, the system can predict increasing deviations from the admissible tolerances with respect to individual quality criteria, which means that deficiencies are not only detected very quickly but can also be predicted. Consequently, the number of quality defects will decrease significantly. This will then increase production throughput, while reducing costs and minimizing rejects at the same time.

However, the ICS quality assurance solutions are only as good as the database: The enabling technology integrate_it allows machine data to be collected, standardized and used in quality assurance, for instance. This involves the data protocols of virtually all machines and equipment being obtained and made available to downstream systems and applications in standardized form.

Live demonstrations and conversations with experts at Motek 2024

Under the motto “We supply the software for the hardware”, the visitors to Motek 2024 are cordially invited to visit MHP on Stand 3103 in Hall 3 to experience live demonstrations and have informative conversations with our experts. The ICS team will be available to talk to you about the solutions in detail and in practice. Interviews can be arranged upon request at any time and at the venue.

In addition, Marcel Heckner (Sales Lead ICS) and Simon Weiß (Portfolio Lead ICS) will give a presentation on “How to use data in production – insights of successful quality assurance optimization” at 13:00 hours on 10th October 2024 in the FORUM (Stand 5435) in Hall 5.