- SaaS (Software as a Service) product bolt_it is an AI-based solution with a manufacturer-independent overview of screwing process data

- Faster quality assurance decisions through intelligent use of screwing process data

- Newest SaaS product from the Industrial Cloud Solutions (ICS) division

- Artificial intelligence can fully unlock the potential of process data, benefiting product quality and production efficiency

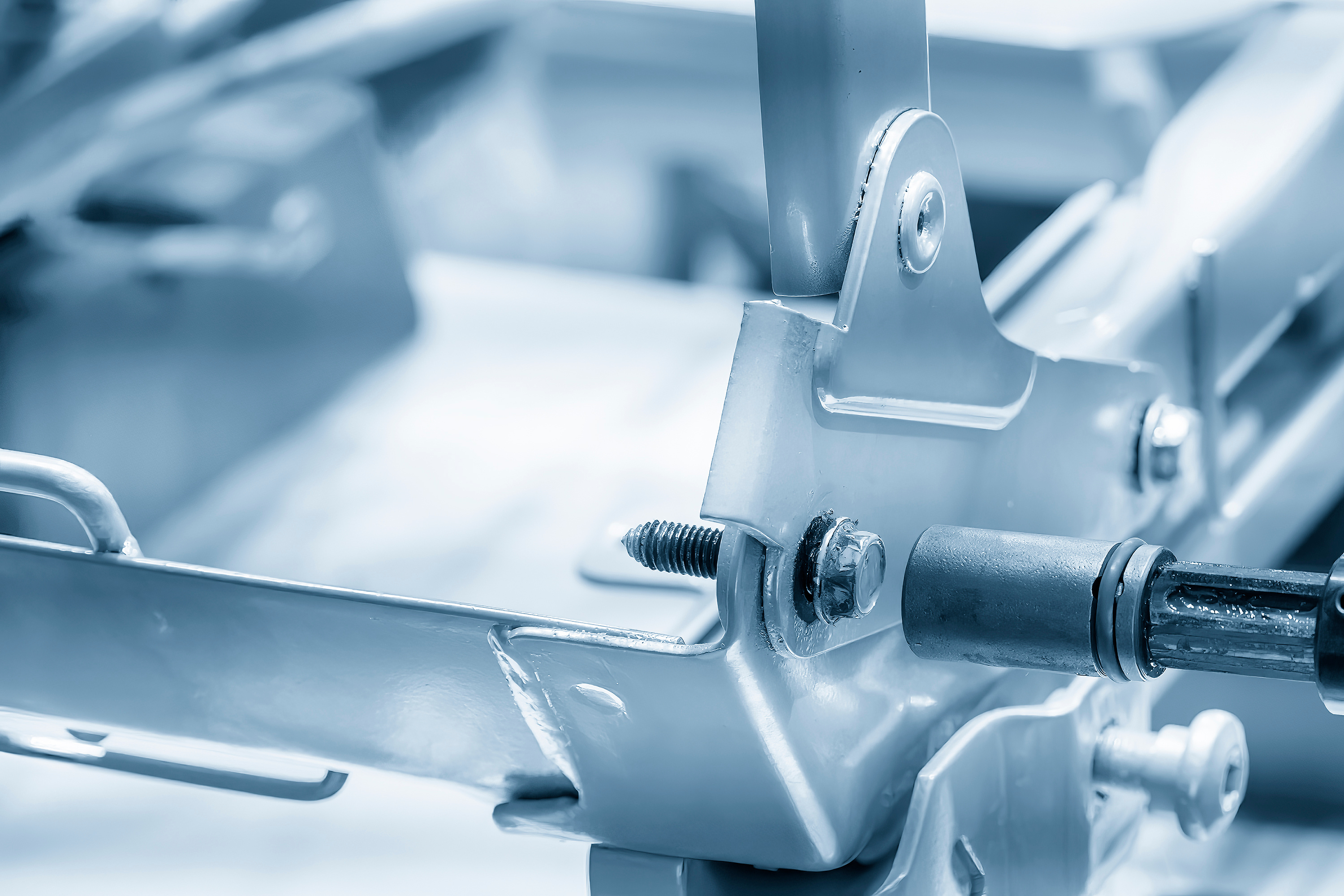

Ludwigsburg – MHP is expanding its Industrial Cloud Solutions (ICS) portfolio with the addition of new SaaS product bolt_it. The management and IT consultancy is thus taking the next step in optimizing production processes and quality assurance in production. A large amount of added value is based on screw processes in assembly. Current challenges are primarily the late detection of problems, the extensive effort involved in manual rework or analyzing defective parts, and the lack of knowledge transfer for preventing similar problems in the future.

With intelligent software solution bolt_it, process data can be monitored in order to troubleshoot problems and anomalies can be detected at an early stage by analyzing historical data. Process control is based on indicative specifications, expert knowledge, and known errors. Data is precisely analyzed by AI, which transmits it to quality engineers and factory and production workers. This saves costs and time, while transparent data insights result in higher quality in production. Four more add-ons to expand functionality are also in development, including an error classification function and a process recommendation function for employees.

Improved quality and increased efficiency

The anomaly detection function was tested in a production plant assembly line at automobile manufacturer Porsche. The quality of bolting processes has been significantly improved with the help of bolt_it: process anomaly detection is seven times greater and screw processes need up to 70 percent less rework. Around 90 minutes per week are also saved for manual data analysis and parameter optimization per production line. The software is compatible with all commonly used industrial power tools. Via a web-based user interface, it provides a manufacturer-independent, customer-specific overview of data in the process, creating a closed loop effect.

Product presentation at Hannover Messe 2024

MHP presented the new business area ICS and the first products paint_it and Sounce for the first time at Hannover Messe #HM23. One year later, MHP is now showcasing its sixth ICS product: bolt_it will be presented for the first time at #HM24 (22–26 April in Hanover).

At the world’s leading trade fair for the industry, around 4,000 companies from engineering, the electrical and digital industry, and the energy sector will showcase their technologies and solutions for an interconnected and climate-neutral industry.