- Barometer results show that, overall, industrial companies in all countries have made progress compared to the previous year – despite ongoing difficult conditions.

- The biggest obstacle to the introduction of Industry 4.0 technologies is the shortage of skilled labor.

- China has taken the lead in almost all aspects of Industry 4.0, but particularly in industrial AI; the US is ahead of the DACH region especially in autonomous systems.

- Data silos and a non-continuous exchange of data are delaying the introduction of Industry 4.0 technologies even in China.

- 94% of Chinese respondents say they already use AI-based solutions in manufacturing processes; in the DACH region this figure is just 20%.

Ludwigsburg/Munich – The digitalization of industry is continuing to advance worldwide. In fact, progress has accelerated again compared to the previous year – despite difficult conditions overall. That is a key finding of the Industry 4.0 Barometer published by MHP management and IT consultancy in conjunction with LMU Munich. The study surveyed 856 representatives from industrial companies in China, the US, Germany, Austria, Switzerland, and the UK.

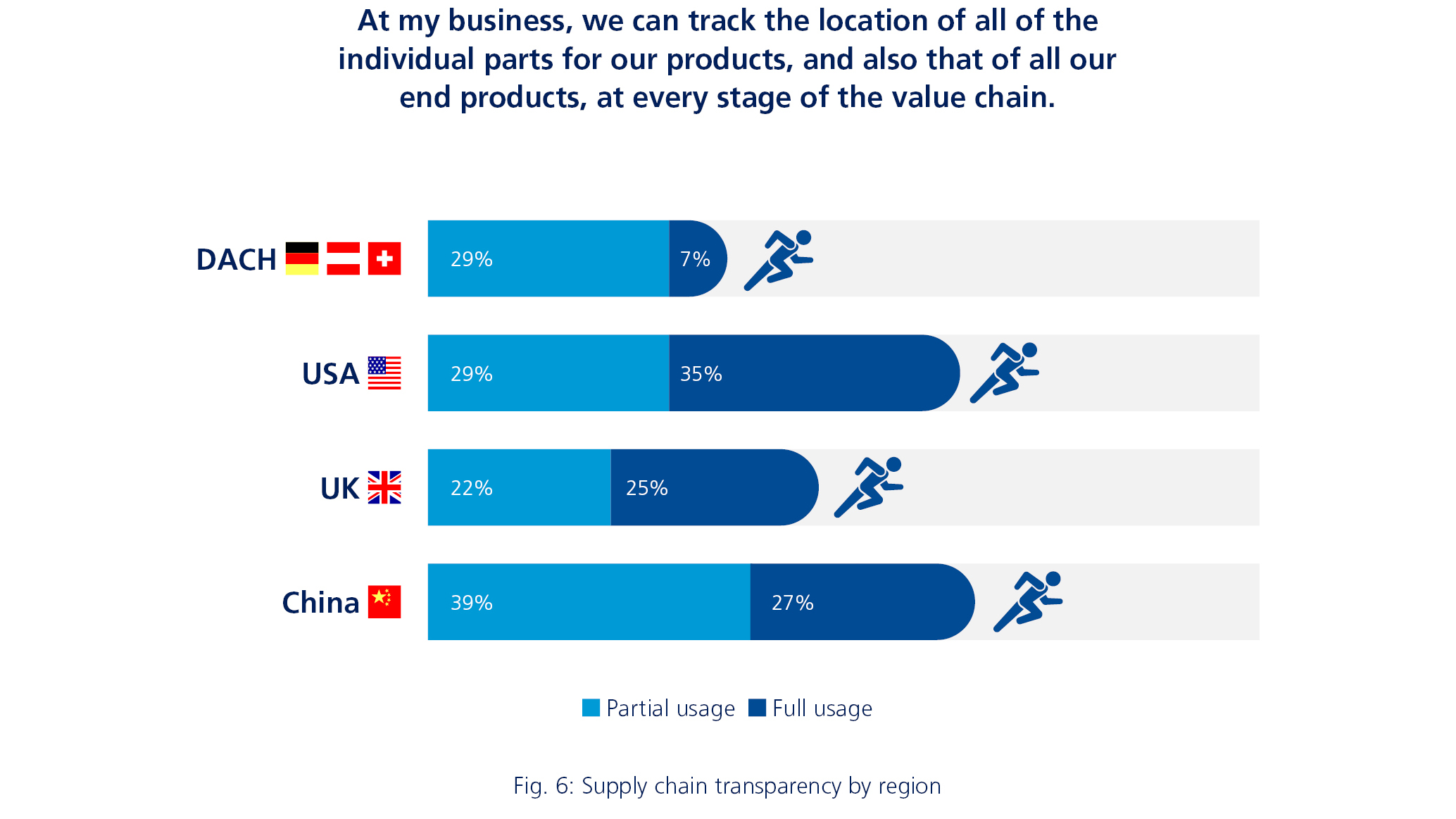

“We registered a positive trend for all technologies,” said Prof. Christina Reich of FOM University and a manager at MHP. “For example, we see from the Barometer result of 60% for tracking technologies – which is 11 percentage points more than in 2023 – that in this area, even more technologies for tracking the location of individual parts of products or end products along the value chain have been partially or fully deployed than last year. This figure was 49% in 2023 and 43% in 2022. So we are on a steady and positive path here.”

Regional differences are clear

However – as in the past – clear differences are apparent when comparing individual countries. In China, 66% of the participants surveyed said they partially or fully use tracking technology, compared to 64% in the US, 47% in the UK and only 36% in the DACH region. Moreover, 30% of respondents said they have no plans to change this situation.

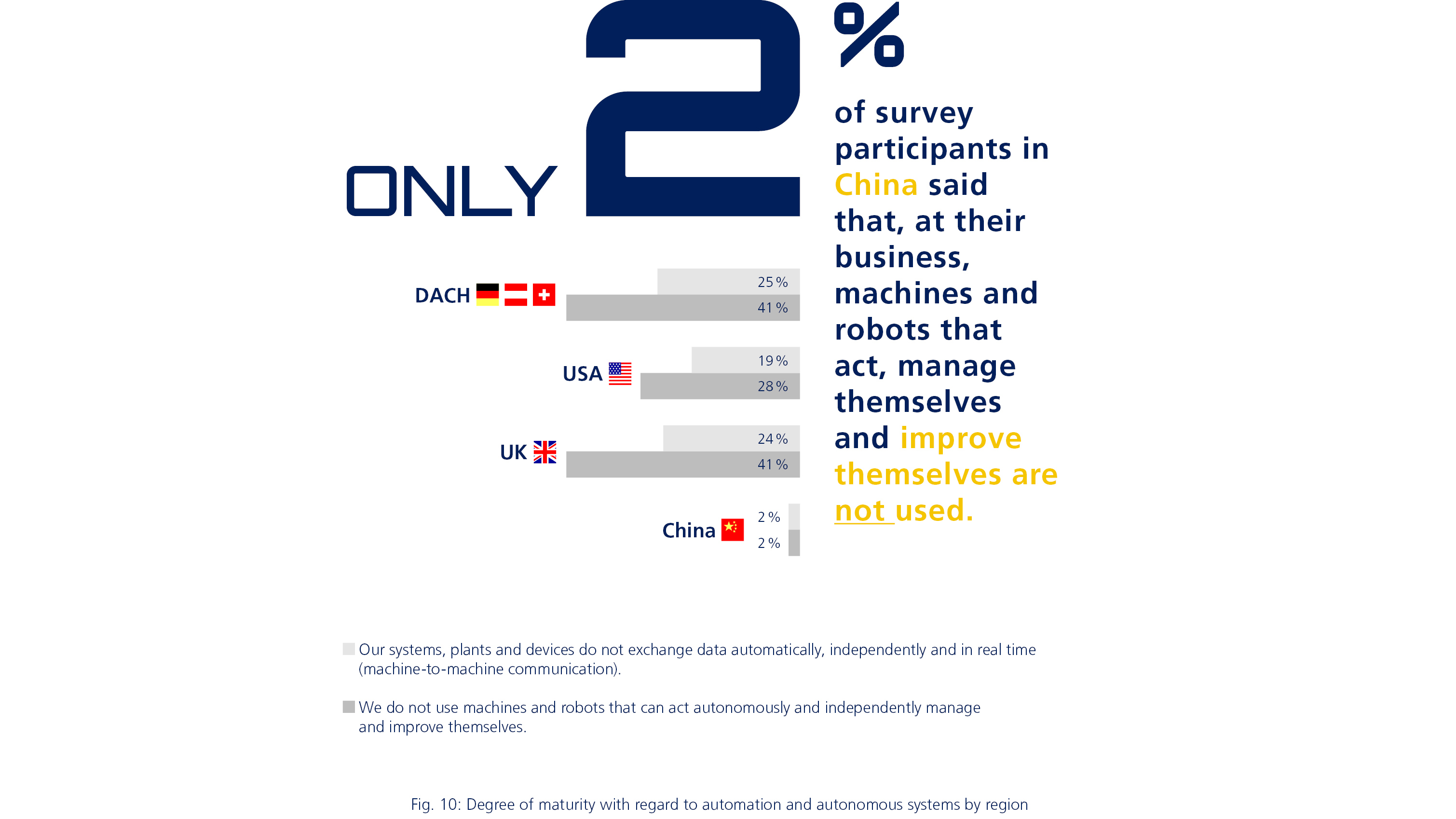

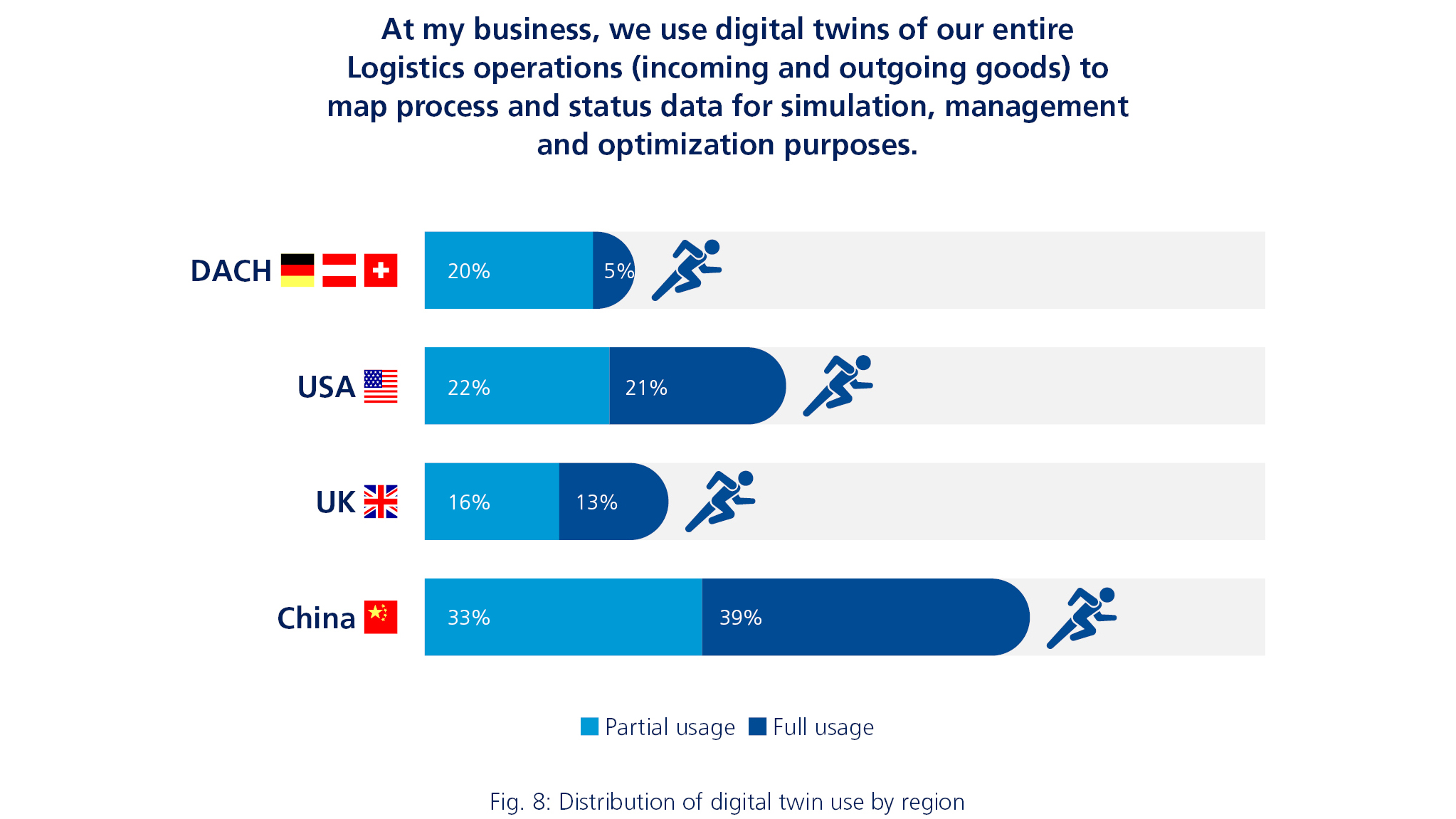

The differences are even more stark when it comes to digital twins. In China, 72% of the companies surveyed have partially or fully established a digital twin of their entire logistics operations to map process and status data. This figure is 43% in the US, 29% in the UK and 25% in the DACH region. And while 41% of respondents in the DACH region said they did not use autonomous machines or robots, 28% said this in the US and only 2% in China.

AI potential is recognized but not yet used consistently

Prof. Christina Reich said: “Essentially, this is the picture for all Industry 4.0 aspects: China leads by a considerable margin – meanwhile, even the US is lagging a good way behind almost everywhere. The UK then generally follows in third place. It is mostly the DACH region that has the biggest need to catch up.”

This is also the case for industrial AI, which was the focus of the survey this year. In China, 94% of the companies surveyed already use AI-based solutions in their manufacturing processes. That is more than twice as many companies as in the US, which follows with 46%. In the UK, 29% of respondents said they used AI-based solutions, while the figure in the DACH region was 20%. This divergence is particularly noteworthy because 6% of all respondents rate the impact of AI in manufacturing processes as fundamental in the coming years, 22% as very high, 32% as high and 27% as at least moderate.

“Everyone has recognized the huge potential of industrial AI. So from our point of view, it is all the more alarming that particularly in the UK and in the DACH region people are missing out on leveraging this potential,” said Prof. Johann Kranz, Professor of Digital Services and Sustainability at LMU. A key reason for the clear differences between the countries as regards AI-based solutions is the shortage of appropriately qualified employees. In China, 88% of respondents agreed that they had sufficient team members to carry out work in AI projects. In the DACH region only 36% affirmed this.

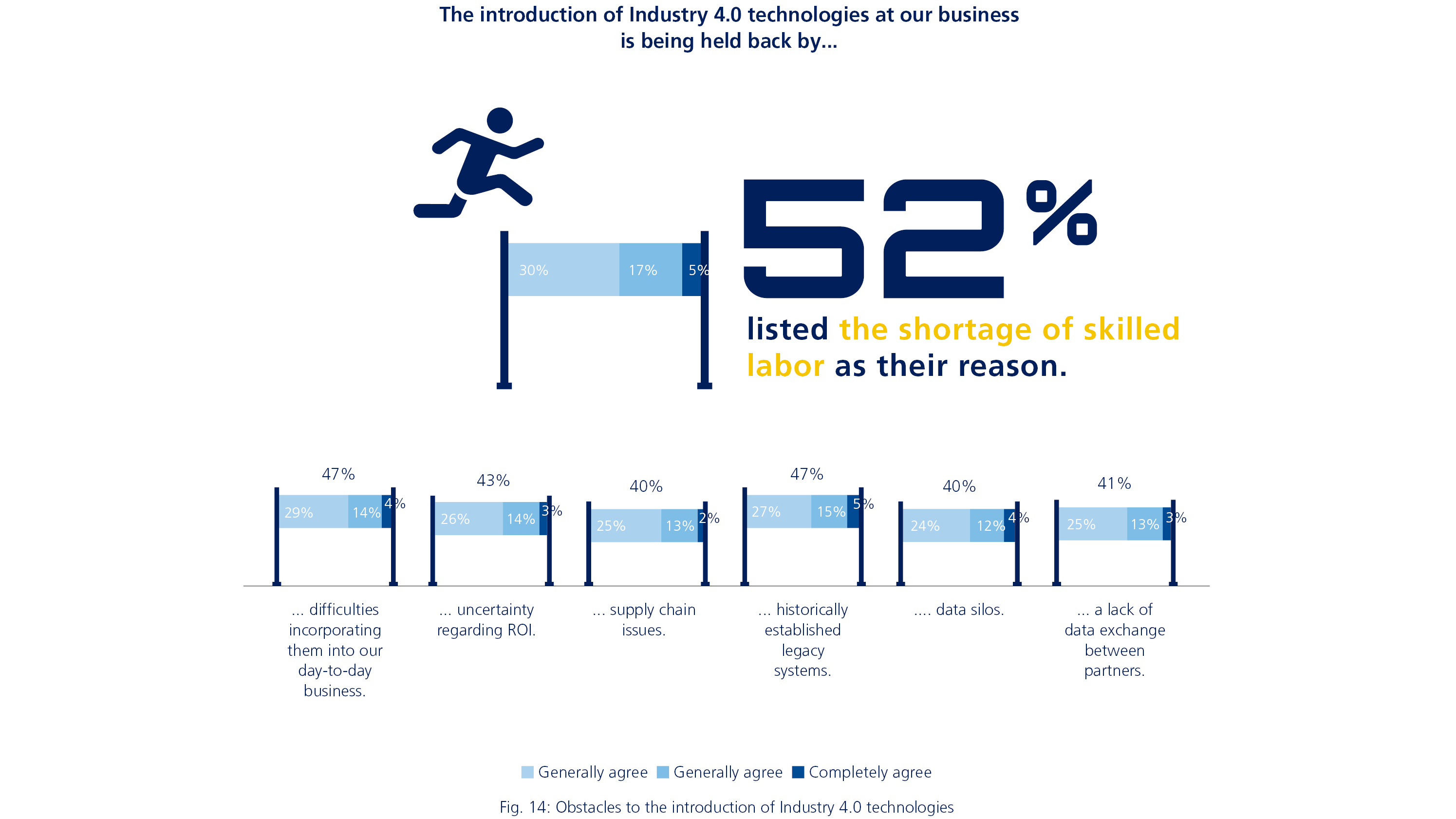

Shortage of skilled labor is the biggest obstacle

The shortage of skilled employees is the biggest obstacle to the introduction of industry 4.0 technologies. Globally, 52% of respondents believe this to be the case. The second and third obstacles are the presence of legacy systems (i.e. outdated or incompatible company software) and the complicated integration into day-to-day business, with 47% agreeing in each case. It is noteworthy that, last year, uncertainty regarding return on investment was the most frequently mentioned argument, at 67%. In this year’s survey, only 43% of respondents agreed with this.

If a company’s Chief Information Officer (CIO) is part of the management team, this has a highly positive impact on the introduction of Industry 4.0 technologies and the implementation of AI projects. Where this is the case, companies perform better in all aspects. For example, participants from such companies rate their own AI maturity level 91% higher than participants from companies without a CIO in the management team. Their satisfaction with the financing of AI projects is even higher. China’s leading position in almost all Industry 4.0 and industrial AI aspects can therefore also be explained by looking at the role of the CIO. At 48% of all the companies surveyed, the CIO is part of the management team. In China, this figure is 83%.

About the Industry 4.0 Barometer 2024

The Industry 4.0 Barometer 2024 is published by MHP management and IT consultancy in collaboration with LMU Munich. The survey was conducted for the sixth time in 2023 and involved 856 participants from industrial companies in China (248), the USA (204), the DACH region (203) and the UK (201).

For the purpose of comparability each year, the survey questionnaire covers the four topic clusters of technology, IT integration, strategy and goals, and obstacles and drivers. In addition, the focus topic of industrial AI was explored in greater depth this time. The empirical part is supplemented with interviews with various experts and the presentation of successful Industry 4.0 use cases.

The full study can be downloaded here. We are happy to provide further information and arrange interviews with MHP experts at any time upon request.

MHP at #HM24 Hannover Messe 2024

The world’s leading trade fair for the industry, Hannover Messe, will take place this year on April 22–26. Around 4,000 companies from engineering, the electrical and digital industry, and the energy sector will showcase their technologies and solutions for an interconnected and climate-neutral industry. MHP will be there again in 2024 (Hall 15, Stand D76) to present new, digital solutions for Industry 4.0. These include bolt_it, a new SaaS solution from the industrial cloud solutions portfolio, and options for implementing an industrial metaverse in production.