- Newsroom

- Published on:

Using smart software for intelligent production and intralogistics

- MHP will have a booth at automatica 2025 (June 24–27, 2025)

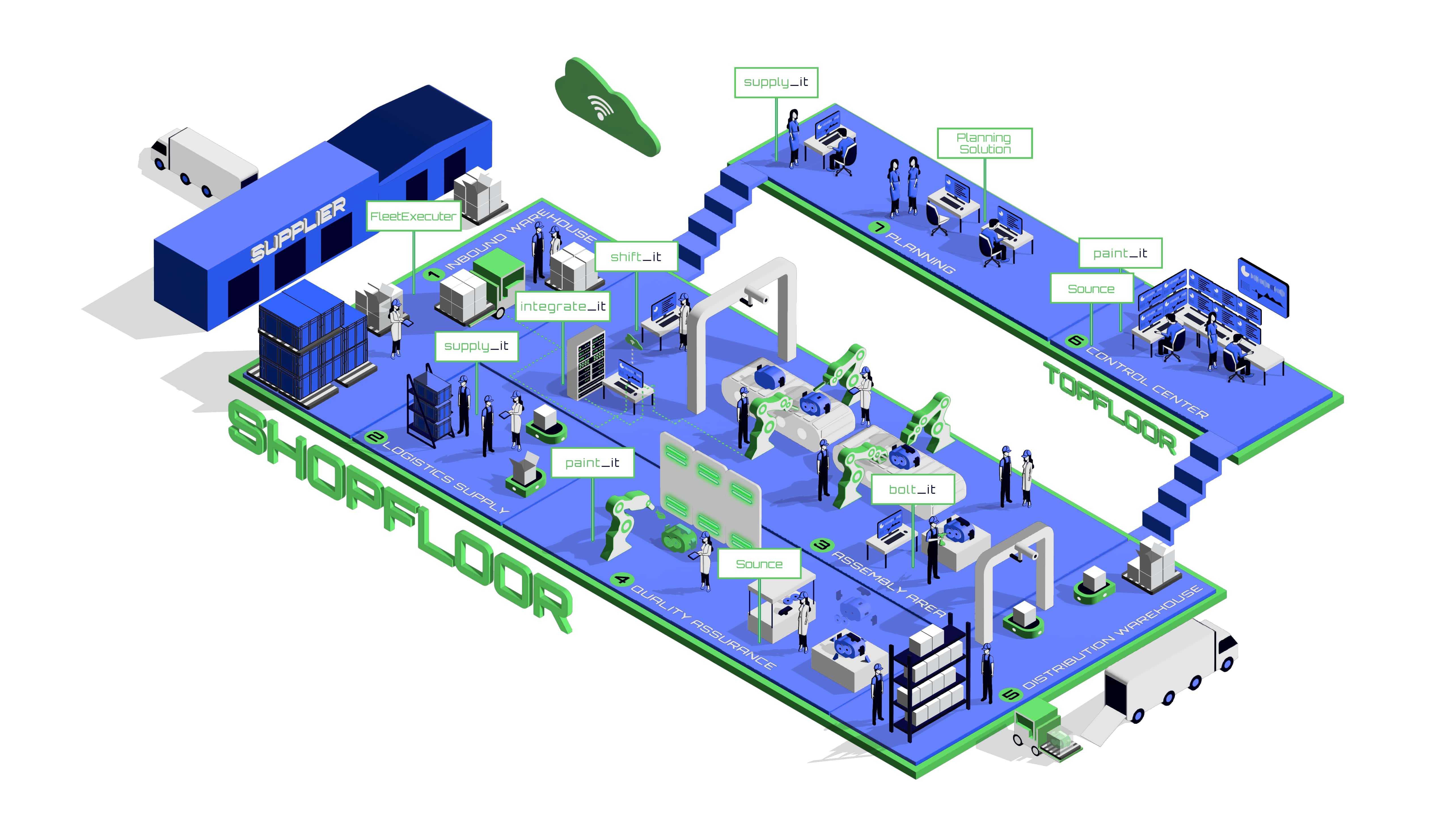

- How smart automation in production and intralogistics – in the form of the software solutions Sounce, paint_it, bolt_it, integrate_it, FleetExecuter, supply_it, and shift_it from MHP’s ICS portfolio – lead to greater efficiency

- Mesh-Up 2025: In a live demonstration on a 600 m² course, MHP will provide its FleetExecuter master con-trol software to control a mixed fleet using the VDA 5050 standard

Ludwigsburg – For the very first time, MHP will have a booth at automatica, the leading exhibition for smart automation and robotics, in Munich. From June 24 to 27, 2025, the management and IT consultancy will be exhibiting all of its in-house developed software solutions from the Industrial Cloud Solutions portfolio (ICS) in Hall B6, Booth 6.139.

Markus Wambach, Group COO at MHP: “Over the past two years, we have been developing our cloud solutions for smarter production and logistics with the aim of helping companies to adopt more efficient and sustainable processes. We now have a well-rounded portfolio of seven products in the areas of quality, intralogistics, and the shop floor, taking production and logistics to the next level.”

All seven solutions will be presented at automatica, including Sounce, bolt_it, and paint_it in the area of quality assurance, which use AI and smart algorithms to optimize testing and control processes. An insight into end-to-end digitalization along shop floor assets is provided by integrate_it. The software-as-a-service solutions supply_it and FleetExecuter show how intralogistics processes can be more efficiently controlled and optimized, while shift_it is the solution for short-term employee scheduling and operational requirements planning across different departments.

Highlight: Mesh-Up 2025 – FleetExecuter navigates a 600 m² course

“Mobile Robots in Production” – a special area at automatica occupying more than 600 m2 at Booth 330 in Hall B4 – will present a showcase demonstrating how various automated guided vehicles (AGVs) and mobile robots from different manufacturers can be operated flexibly and efficiently using the VDA 5050 standard. MHP will provide the master control software for the heterogeneous fleet during the live demo.

Michael Appel, partner at MHP: “The MHP FleetExecuter was selected primarily because it can control a wide range of AGVs and mobile robots made by different manufacturers. Visitors to the exhibition will see how full and empty containers are transported and delivered by different devices along a production process. Both platform trucks and forklift trucks for transporting pallets will be used alongside mobile robots that transport Euro containers. There will be a total of ten automated guided vehicles (AGVs) from eight manufacturers, including Bosch Rexroth AG, KUKA AG, and SAFELOG GmbH.”

The showcase is being organized as part of automatica in conjunction with the VDMA from June 24 to June 27, 2025.

ICS solutions at automatica in detail

All ICS solutions have one thing in common: They are cloud-based and flexible, which means they can be hosted on the platforms of all hyperscalers, such as Amazon Web Services (AWS), to guarantee high availability and easy scaling. They can also be integrated as on-premises solutions.

Quality assurance based on AI: Sounce, paint_it, bolt_it, and integrate_it

AI-based, acoustic quality control is possible with the aid of Sounce: The solution has been used in the assembly plant at Porsche for over two years, as well as at other OEMs and suppliers such as KUKA. Noise anomalies help to detect errors automatically and in real time when inspecting chassis components.

Quality assurance in the paint shop can be automated and optimized with paint_it. Using intelligent analysis, quality defects in the paintwork can be detected and, to a certain extent, predicted within a very short space of time – and this is already being done successfully at German OEMs.

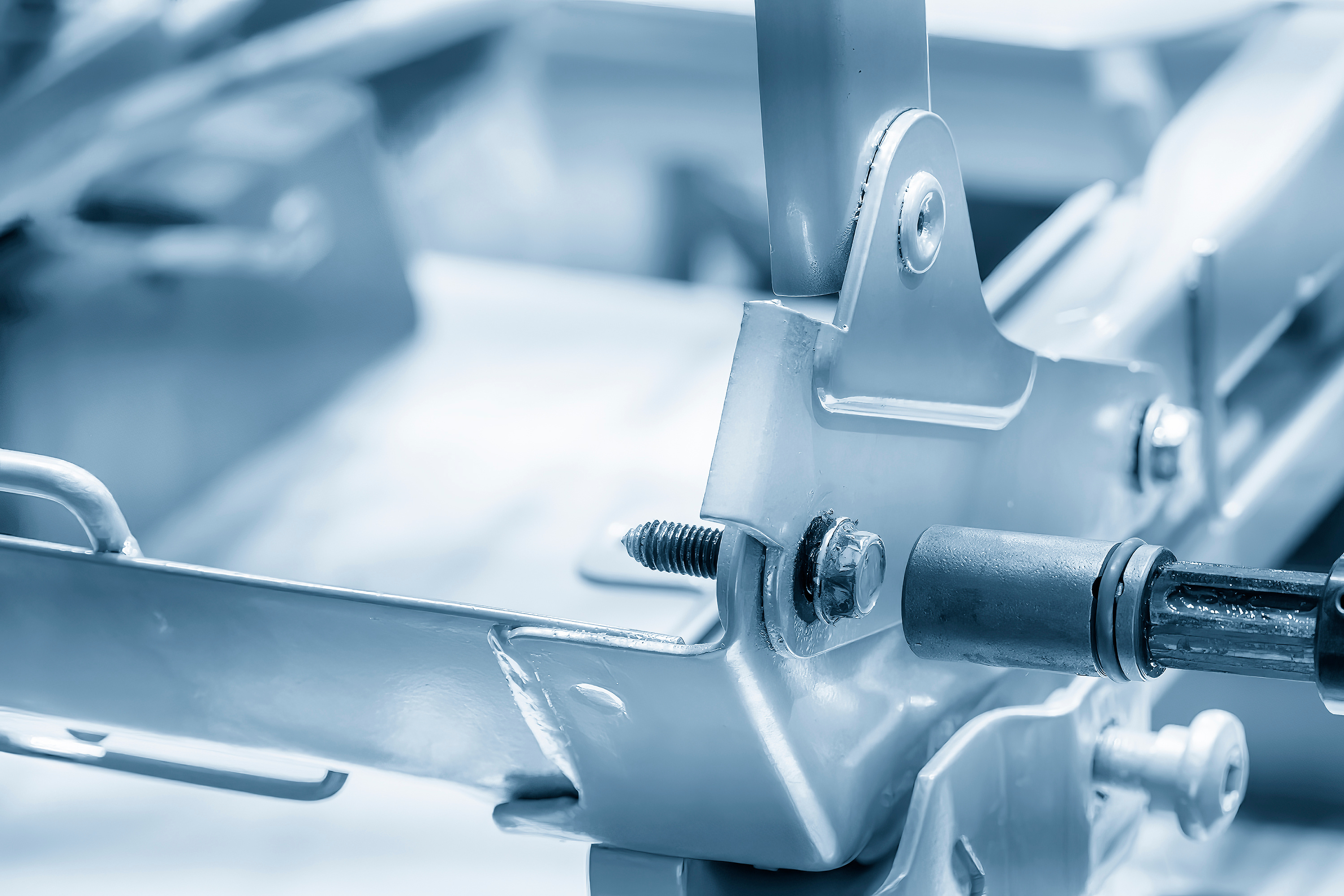

With bolt_it, unknown faults in the bolt connection can be detected using AI. The software detects anomalies, regardless of the manufacturer or tool, reducing the risk of product recalls and the associated workload and expense. The intelligent test system for analyzing bolting process data is used by Porsche and Bentley, among others.

With the aid of the innovative middleware integrate_it, data from machines and systems made by almost all manufacturers can be collected, transformed, and distributed, enabling end-to-end digitalization from the top floor to the shop floor. The integration process is also easier when connecting machines.

Intralogistics: FleetExecuter and supply_it

FleetExecuter, the central and manufacturer-independent fleet management control system, has been in use at Faurecia for several years and at Porsche in Zuffenhausen since last year. It controls 27 AGVs over a distance of 750 meters, split over two floors, with up to 106 loads transported per hour. The project received the Allianz Industrie 4.0 Award. It was also nominated for an IFOY Award at Wildeboer, where FleetExecuter controls six AGVs and a SOTO (Magazino, Jungheinrich).

The intralogistics solution supply_it also makes it possible to optimize material flow planning. It is being used at Porsche for 911 production, where it helps to perform scenario analyses that show the most cost-effective option for making sure that the required components are available in the right place at the right time without different material flows blocking one another. This can save up to ten percent of the intralogistics costs.

Shop floor: shift_it

The SaaS solution shift_it provides a comprehensive overview of all employee scheduling along with the qualifications of the employees stored in the system, making it possible to react to acute staff shortages on shifts at short notice. This cloud solution can reduce the amount of time spent planning each shift for the various trades by up to 20 minutes.

Would you like to find out more about our customer projects? We will be happy to talk to you in advance and provide you with additional material. If you would like to talk to us at the exhibition booth, please feel free to get in touch with us.

For the first time, MHP will have a booth at automatica, the leading exhibition for smart automation and robotics, in Munich. (photo: Adobe Stock)

MHP FleetExecuter at Porsche (photo: MHP)

Infographic: ICS Shopfloor, Overall overview (photo: MHP)

MHP supply_it (photo: Adobe Stock)

MHP bolt_it (photo: MHP)

MHP Newsroom

Need information about MHP or our services and expertise? We are happy to help and will gladly provide you with current information, background reports, and images.