- Cloud

- Published on: 20.02.2025

How MHP and AWS Are Sustainably Transforming Porsche's Order Management with an Analytics Platform

Unified, Efficient, Future-Oriented

Setting New Standards for Data Integration: From Data Silos to Real-Time Data

As part of a forward-thinking initiative, Porsche and MHP worked together to fundamentally transform the data landscape for order management and unlock new opportunities. The following challenges were successfully addressed:

- Fragmented Data Sources: Information on order intake, inventory levels, or cancellation data were scattered across multiple systems. These isolated systems made it difficult to achieve a unified view of relevant data, complicating planning and control processes.

- Lack of Real-Time Analytics: The previous systems operated on daily data, meaning changes and updates within a day were not immediately visible, significantly limiting the accuracy and speed of data-driven decisions.

- Manual Processes: Employees often had to create and update reports manually, which was not only time-consuming but also prone to errors. Automated processes were virtually non-existent, causing a loss of efficiency.

- Complex Requirements Due to Market Dynamics: The increasing complexity of the vehicle lineup and dynamic developments in global markets created a greater need for precise, flexible, and fast data analysis.

All Vehicle Data in One Place: How MHP and AWS Developed an Efficient and Future-Proof Reporting Architecture for Porsche

To address the challenges, MHP developed a modern, scalable reporting architecture based on AWS. This flexible system architecture integrates all relevant data sources, providing a consistent "Single Source of Truth" (SSoT) that meets both operational and analytical requirements.

Core architecture and AWS services

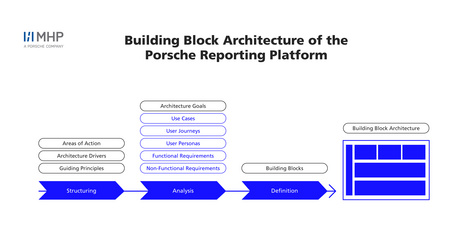

The platform is based on a modular building-block architecture, specifically tailored to meet the complex requirements of Porsche. It integrates key functions such as event-driven data processing, KPI calculation, and reporting.

Amazon Redshift: Provides a high-performance, centralized database for storing and analyzing large data volumes. It enables the real-time calculation and aggregation of key performance indicators (KPIs).

AWS Lambda: Supports event-driven data processing, allowing for real-time updates and calculations.

Apache Kafka (via AWS): Acts as a message bus and enables the synchronization of data streams, ensuring that all relevant information is available both operationally and analytically in real-time.

Amazon S3: Provides scalable storage for large data volumes, ensuring long-term, secure data archiving.

This architecture clearly separates the calculation of KPIs from the reporting layer built on top of it. This boosts system performance and allows for seamless scalability. Through real-time data synchronization, users have access to consistent and up-to-date information, enabling them to make faster, more informed decisions and manage their processes more efficiently.

Flexibility and scalability with data mesh

To address specific use cases such as vehicle status distribution reports or sales analyses by market hierarchy, the architecture was expanded with customized data products within a Data Mesh framework. This structure simplifies the integration of new technologies, such as AI-driven analytics, while ensuring high scalability.

Designed with in-depth understanding of internal processes

MHP collaborated closely with Porsche's sales team to gain a deep understanding of the specific requirements and needs for the reporting solution. Through dedicated workshops, MHP ensured that the solution was seamlessly integrated not only on a technical level but also in alignment with organizational workflows.

Agile and flexible: developing the solution architecture with AWS

Based on the defined requirements, a reporting solution was developed leveraging AWS analytics services and serverless technologies.

Iterative Development: The architecture was built modularly and deployed in phases, enabling early access to critical features.

Rapid Rollout: The first version, covering key metrics like order intake, cancellation rates, and order backlog, was launched within three months.

Direct Feedback: The iterative approach allowed for immediate user feedback, driving continuous optimization of the platform.

Unified Data Foundation and Real-Time Analytics: Results of the New Reporting Platform

The implementation of the AWS-based reporting platform has enabled Porsche to tackle key challenges while significantly enhancing the efficiency and quality of data-driven decision-making:

Faster and more Accurate Decisions

Real-time data processing allows immediate recognition of changes in order status, integrating them into decision-making processes. This increases agility and improves precision in planning and control.Reduced Errors and Automated Processes

Automation of report generation and the integration of a centralized data foundation minimize manual intervention, reducing error rates and saving valuable time.Improved Data Consistency and Transparency

The centralized "Single Source of Truth" ensures that all departments work with the same consistent data. This strengthens cross-departmental collaboration and creates transparency throughout the organization.Foundation for Future Innovations

The platform's flexible and scalable architecture allows Porsche to quickly integrate new use cases, such as AI-based forecasts or additional metrics like dealer quotas and delivery reliability.

Porsche, MHP, and AWS: A Partnership Setting Pioneering Standards for the Future

The close collaboration between Porsche, MHP, and AWS was the cornerstone of this project's success. Through an iterative development approach – characterized by workshops and continuous exchange – the solution was precisely tailored to meet the requirements of Porsche's order management processes.

A significant milestone was the phased rollout of the platform, which enabled the deployment of key features within just three months. This approach not only allowed early user feedback to be integrated but also facilitated rapid improvements and noticeable process optimization.

The result is a modern reporting architecture that impresses with its centralized "Single Source of Truth," real-time analytics, and flexible scalability. This solution not only enhances the current order management processes but also lays a future-proof foundation for innovations such as AI-powered forecasts and analyses of dealer performance and delivery reliability.

Are you looking for an innovative solution to optimize and future-proof your order management? Together with our partners like AWS, MHP supports companies in overcoming the challenges of digital transformation and achieving sustainable success. Contact us to learn how we can help your business set new benchmarks in data and system integration.