- Newsroom

- Veröffentlicht am:

Forward-looking Production with Software Defined Manufacturing and AI

- MHP as Platinum Partner of Amazon Web Services (AWS) in hall 15, stand D76

- Software Defined Manufacturing and AI showcases and presentations

- Festo exhibit: Visualization of central machine control with the aid of AWS cloud and NVIDIA Omniverse

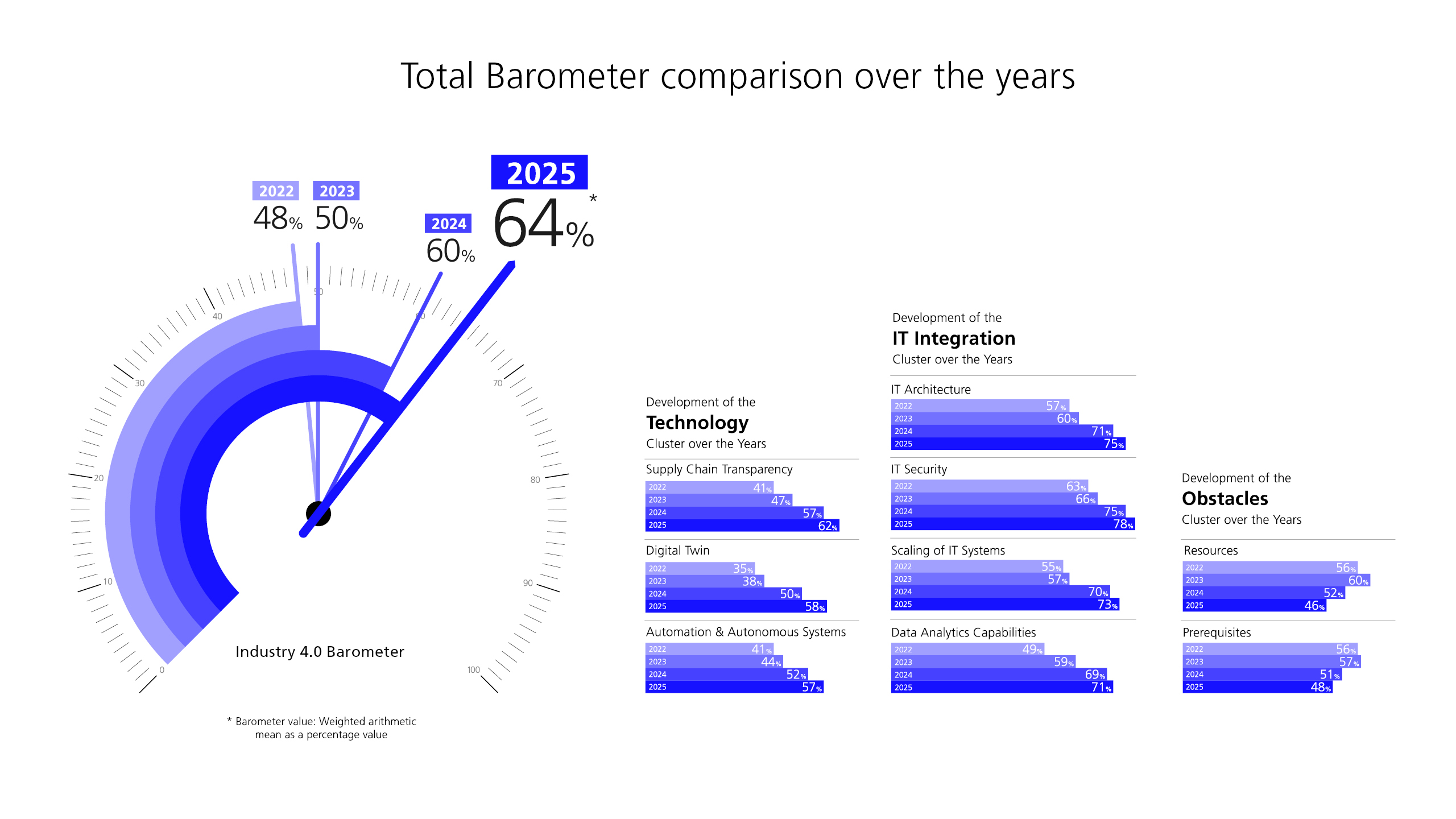

- Industry 4.0 Barometer 2025: International progress in the use of Industry 4.0 technologies

Ludwigsburg – Agile transformation and preparedness for technological changes are becoming core competencies for companies worldwide in economically turbulent times. Software Defined manufacturing (SDM) has exceptional potential as a basis for forward-looking, highly efficient production. How this works in practice will be demonstrated by MHP management and IT consultancy from March 31 to April 4 on the AWS partner stand at Hannover Messe.

Federico Magno, Group CEO of MHP: “As an AWS Platinum Partner at Hannover Messe, we’ll show how digital innovation is securing the future of industry. With a view to the growing challenges caused by deindustrialization and global competitive pressure, Software Defined Manufacturing and Industrial Cloud Solutions are the key to resilient, efficient, and sustainable production. Our innovative cloud technologies and customized solutions create a tangible impact by enabling companies to flexibly configure, optimize, and continually refine manufacturing processes for a competitive industry in Europe and beyond.”

SDM revolutionizes production environment

SDM describes production in which the control software is almost completely decoupled from the hardware of machines and systems – the software is on a central platform. Through this separation and the comprehensive digitalization of manufacturing and machine processes, an intelligent production environment is created that can be quickly and easily adapted to new requirements “at the touch of a button”. It remains continuously highly efficient as an overall system through updates and upgrades. The digital twin plays a key role here. Integrated in SDM, digital twins can not only reflect the current state of production, but also be dynamically adjusted and optimized. Using a scaled down Festo training factory as an example, MHP will demonstrate how factories can be digitally simulated in NVIDIA Omniverse. The software runs decoupled from the machine in the AWS cloud – for this, data is collected, transformed, and made analyzable with the integrate_it ICS solution developed by MHP. The centralized control of all machines creates a measurable improvement in performance of the production process.

Faster decisions with AI

Alongside SDM, AI remains the driving force behind digital transformation. AI redefines efficiency and delivers scalable results, real-time process optimization, energy savings, and increased productivity – even with limited resources. Through AI-supported automation and data-based insights, precise and complex decisions can be made faster and more effectively.

“With the aid of cloud technologies like AWS, data analysis, and AI, companies can dynamically adapt their production lines to maximize quality and throughput without being dependent on physical hardware changes. This makes production more agile, intelligent, and future-proof,” says Markus Wambach, Group COO of MHP. He adds: “Digital twins and AI solutions represent established technologies that can be implemented in companies. The basis for this is an appropriate data strategy.”

Industry 4.0 Barometer 2025: Companies are making progress

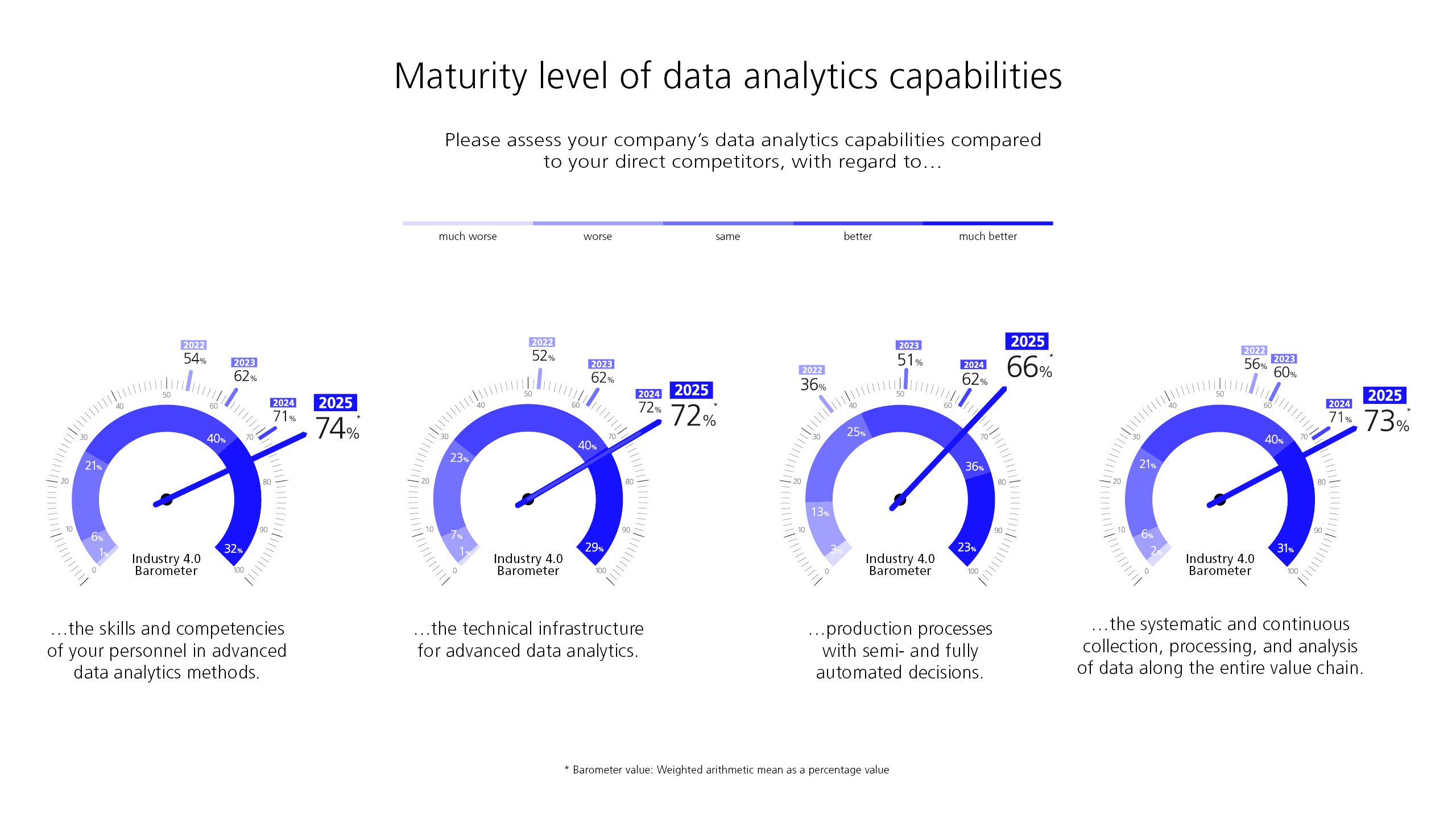

MHP will also present the new Industry 4.0 Barometer 2025. This year, the focus is on data-driven production. Companies around the world are making further progress in using Industry 4.0 technologies, but not as quickly as before. The difficult market conditions may not be hindering digitalization, but data expertise is lagging way behind in the DACH region (Germany, Austria, Switzerland). In the long term, the German-speaking region could fall even further behind China and the US.

Many companies still do not have an appropriate strategy and are failing to use their own data efficiently along the entire value chain. Data silos and lack of interaction are hampering digitalization. The maturity level of data analysis capabilities also shows a significant lag. “Digital transformation is a mammoth task – and it can’t be delegated. A clear data strategy with a target vision for technology and a way out of data silos to consistent data integration are crucial. Data quality needs to have the same importance as traditional KPIs,” says Christian Fiebig, partner at MHP. “Companies should therefore invest in digitalization especially now and prepare the ground for modern technologies.”

Presentations and showcases at Hannover Messe

Other projects and topics will be presented by MHP experts in presentations and showcases at #HM25. The focus will not only be on the modernization of the AGV fleet at VW Saxony, but also the improvement of business processes with SAP Signavio and the MHP POLARIS method using the example of Bauer AG.

Information on the presentations and showcases can be found at the MHP stand in the AWS area, hall 15, stand D76 or on our website: https://www.mhp.com/en/hannovermesse2025

Would you like to arrange a meeting with one of our experts? Please feel free to contact us in advance. We look forward to seeing you.

MHP Newsroom

Sie benötigen Informationen zu MHP oder zu unseren Leistungen und Kompetenzen? Gerne unterstützen wir Sie mit aktuellen Informationen, Hintergrundberichten und Bildern.